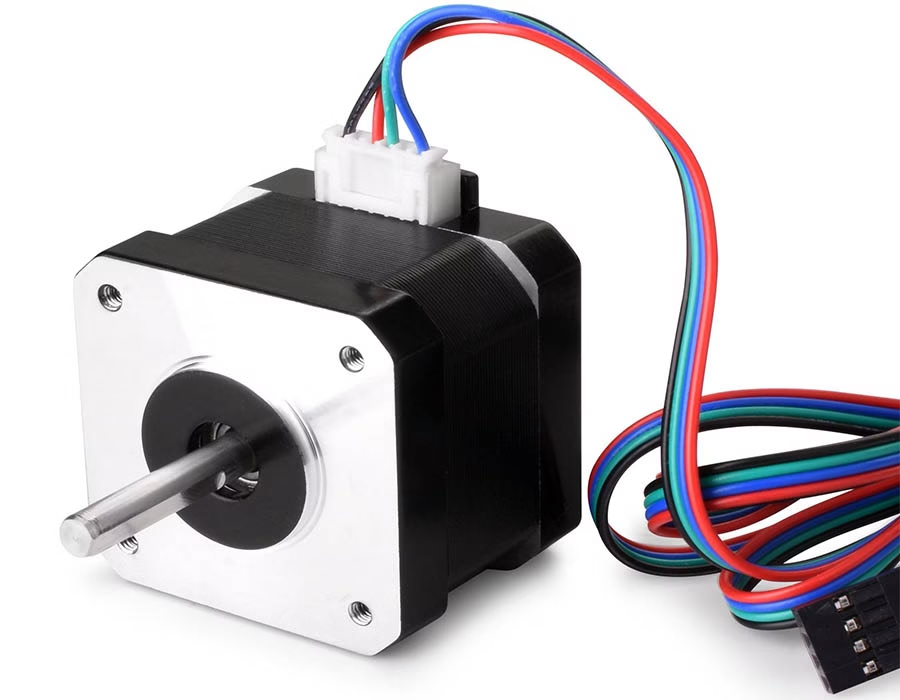

Motor cables transmit power from drives to motors in industrial equipment; therefore, selecting the appropriate cable is crucial. Consider a motor cable assembly to be a carefully engineered bundle of insulated copper conductors that can reliably transport current even under challenging situations. Conductor size, insulation type, shielding, length, and flexibility are all essential elements to consider.

To manage drive spikes, current motor cables are often rated 0.6/1 kV or higher, resulting in shorter cable runs and lower voltage drop. To avoid voltage loss or reflected-wave difficulties, always consult the OEM’s maximum cable length specifications.

Motor Cable Specifications

- Conductor: For flexibility and conductivity, use fine-stranded tinned copper. Long runs or robot joints are easy places for fine-strand conductors to bend.

- Voltage Rating: Motor cables should have a voltage rating of 0.6/1 kV or above. More insulation, like that rated at 2 kV, helps withstand voltage spikes from VFD drives.

- Insulation: Because of its high dielectric and thermal properties, cross-linked polyethylene (XLPE) is widely used. To permit longer runs and improved heat dissipation, it often exceeds the standard code thickness (RHHW-2).

- Shielding: High-frequency noise is produced by inverter-fed motors. For inverter drives, use a shielded motor cable, usually a braided or bonded copper-foil shield with at least 80% coverage. By blocking EMI, this “Faraday cage” safeguards machinery and stops bearing currents.

- Armor (optional): Optional armor (steel tape or wire braid) provides mechanical protection in heavy-duty situations, although copper tape frequently provides a lower impedance noise channel.

- Length & Gauge: Use motor current (AWG or mm2) to determine the conductor size. To choose the appropriate gauge, use an AWG calculator. Shorten cables as much as possible since they increase capacitance and voltage drop, which can trip drives. Many drives recommend a maximum distance of 50 to 100 meters; if this limit is exceeded, output chokes or filters may be required.

Keep these specifications in mind when building a cable. For instance, to minimize electromagnetic interference (EMI), a high-power conveyor motor with a VFD requires a 100%-coverage copper foil shield, thick conductor, and hefty XLPE insulation. A high-flex cable with thin strands, silicone or PE insulation, and foil or braid shields may be used by a small robot arm motor to withstand millions of bending cycles.

Cable Construction & Build

Motor wiring harnesses typically consist of more than just conductors. Multiple insulated conductors are bundled, twisted, or sheathed together, with terminal connections achieved via connectors. This harness (or “cable bundle”) simplifies installation by enabling wiring through a single component insertion, eliminating the need for individual wiring.

Premium harnesses feature protective jackets (made of PVC, PU, or TPE) and may incorporate tape or braided layers for enhanced abrasion resistance. Jackets for robotics or industrial equipment combine wear resistance with optimized bend radius design.

For safety and ease of maintenance, high-quality harnesses include clearly visible labeling and strain relief devices. In short, harness assemblies are custom-engineered for specific application scenarios.

- Insulation Layers: Multilayer insulation (PVC, XLPE, silicone) protects against heat, oil, and chemicals.

- Shielding: To prevent interference, an aluminum foil or braided copper layer is typically put beneath the jacket. Foil is commonly used for 100% coverage; however, braid (85% coverage) can also be utilized, sometimes in layers.

- Armor (for extreme use): Steel or aluminum armor provides crush resistance. Useful for mining and marine drives.

Connect design details with tools and services: Use online AWG or cable calculators to determine conductor sizes, and consult with custom cable assembly manufacturers for guidance on connections and configurations.

Shielded Cables for Inverter (VFD) Drives

When your motor is powered by a VFD (variable frequency drive, or inverter), always use appropriately protected cable. VFDs produce rapid PWM voltage spikes, which can result in EMI and bearing currents. To handle these spikes, shielded motor cables for inverter drives commonly use XLPE insulation and dual shielding (foil + braid). The shield should be grounded at the driving end to create a low-impedance return path.

- XLPE Insulation: XLPE insulation can withstand peak voltages (up to 2-4 kV during transients).

- Copper Tape Shield: Many experts recommend using a continuous copper tape shield (with a 50% overlap) for the lowest impedance. This reduces common-mode noise more than braided copper.

- Ground Conductors: Some cables have additional ground conductors (“3x full-size” or 300% ground for small drives) to absorb noise.

- Jacket Options: For industrial applications, use PVC (oil/sun resistance) or TPE (heavy-flex, heat/oil resistance) jackets as needed.

Using the right VFD cable significantly decreases torque ripple and motor stress. In fact, poor or unshielded cables can cause early bearing failure or drive trips.

High-Flex Cables for Robotics

Robots keep cables in constant motion. Flexibility and durability are critical in robotic motor cable assembly. Use ultra-flexible, finely stranded conductors and jackets that have been tested to withstand continuous bending. These high-flex motor cables for robots often feature silicone or specialized PVC insulation and reinforced outer jackets.

- Torsion and Bend Ratings: Robotic arms can twist cables 360 degrees or flex thousands of times without damage. High-flex wires are designed to withstand millions of cycles.

- Heat/Fire Resistance: Welders and motors nearby require flame-retardant and, in some cases, fire-resistant materials.

- Shielding & EMI: Even robot wires transmit data (encoders, sensors). Shields keep signals clean. To block noise from servo power lines, cables in assembly robots employ braided shields.

- Custom Harnesses: Typically constructed as a single harness (bundle) containing numerous cables (power, encoder, braking, and bus) in one jacket. A bespoke robot wire harness ensures the correct lengths and strain relief.

A factory robot arm, for example, may be outfitted with a shielded, halogen-free cable bundle rated for millions of bends and featuring additional heat protection. These customized cables outperform generic wires by a significant margin.

Selecting an Industrial Motor Cable Supplier

When selecting a motor cable manufacturer, look for experience in industrial and automation applications. The provider should provide custom cable assembly and OEM/ODM services. Examine the certifications (e.g., UL, CE, ISO) and tests (impedance, high-pot, vibration). Many cable manufacturers additionally offer tools such as AWG calculators and design guidelines.

- Customization: You typically start with a bespoke quote. The provider should assist you in selecting the appropriate conductor gauge, insulation, shielding, and connector types based on your specifications.

- Sample & Testing: Reliable manufacturers can provide prototypes for speedy testing. They should test the completed cables for continuity, hipot, and flex.

- Turnaround: In B2B markets (US/EU), quick lead times are critical. Some factories complete prototypes in a week and bulk cables in a few weeks.

- Technical Support: The top vendors work as partners, reviewing your wiring schematic, recommending changes, and directing you to resources such as special cable assembly types and product brochures.

If you need help estimating or specifying motor cables, utilize online tools and examine real-world cable assemblies. Connectors such as M8, M12, and M16 are widely used in machine wiring; for more information, please visit our M8/M12 cable assembly page.

Key Takeaway: A suitable motor cable is specifically designed for the application. Balance technical specifications (voltage, current, EMI, flex life) with practical requirements (length, environment). With the proper design, including a copper core, strong XLPE insulation, and adequate shielding, your drive system will function efficiently and reliably.

FAQs

A: Good question. Most people guess… which is precisely why motors overheat.

First, determine the motor’s full-load current and add a safety margin. Then use an online AWG calculator to determine the appropriate wire gauge based on cable length and installation environment.

👉 Quick tool: https://www.romtronic.com/awg-calculator/

For longer runs or when using variable frequency drives, go one size up. Your future self will thank you for this decision.

A: In short, the answer is yes.

Variable frequency drives generate high-frequency noise that can interfere with sensors, trigger unnecessary drive tripping, and even cause long-term wear on motor bearings.

Shielded motor cables confine this noise internally—precisely as they should.

When powering a motor via a VFD, shielding is not optional. It gives you peace of mind.

A: Technically, you could, but you shouldn’t.

Motor cables are designed with stronger insulation and improved EMI management compared to regular power cables. Power cables are not intended to withstand drive output spikes.

If reliability is a top priority, select a cable specifically designed for use with motors. Your maintenance team will thank you.

A: Look for terms like “high flex,” “drag-chain rated,” “torsion 360°,” and “million-cycle tested.”

If none of these are included on the spec sheet, the cable is presumably not intended for robotics.

Robots are unforgiving—if a wire isn’t meant for constant bending, it will fail far sooner than you think.

A: Consider foil shielding to be a tight, high-frequency “noise blanket” that traps unwanted EMI.

Braid shielding is more like armor: it is stronger, tougher, and provides better mechanical protection.

Many high-end motor cables incorporate both, providing the best of both worlds.

A: Absolutely.

Small motors also fail, particularly when paired with low-cost drives.

Even a 5-HP setup benefits from good shielding, grounding, and the appropriate AWG size.

Shielding is crucial for preventing signal noise in shops with multiple machines running simultaneously.

A: Yes—and it’s usually the wiser choice.

Motor cable assemblies are delivered ready to plug in, resulting in fewer wiring mistakes, faster installation, and easier servicing later.

Want to learn about different types of assemblies?

👉 http://romtronic.com/view-more-cable-assemblies-type

A: Here is the easy version:

If you have a VFD, use a shielded XLPE motor cable.

If your cable moves, use high-flex or drag-chain cable.

If your run is long, consider increasing the AWG size by one.

If unsure, use a cable rated greater than your needs.

Simple, safe, and effective.

This article should help you select the appropriate industrial motor cables for your drives. Consider conductor size, insulation, shielding, and flex life to ensure a safe and efficient power supply for your motors. Good luck with your project, and don’t hesitate to contact specialists if you have any further questions.

.avif)

Sam Wu is the Marketing Manager at Romtronic, holding a degree in Mechatronics. With 12 years of experience in sales within the electronic wiring harness industry, he manages marketing efforts across Europe. An expert in cable assembly, wiring harnesses, and advanced connectivity solutions, Sam simplifies complex technologies, offering clear, actionable advice to help you confidently navigate your electrical projects.