Wire gauge refers to the thickness of a wire and is typically expressed by a numerical value. In most gauge systems, a smaller gauge number means a thicker wire. Thicker wires have a larger cross-sectional area, which lowers resistance and allows more current to flow safely. For example, each 3‑step decrease in AWG roughly doubles the cross-sectional area and current capacity. Engineers use wire gauge charts to pick the correct wire for a task, matching gauge to diameter (or location) and ampacity.

American Wire Gauge (AWG)

- Definition: AWG is the U.S. standard for wire sizes, which has been used in North America since 1857. It applies to solid, round, nonferrous wires.

- How It Works: Gauge numbers increase as wire diameter decreases (logarithmically). For example, (4/0) AWG is huge (0.460 inches ≈, 11.7 mm), while 40 AWG is excellent (0.0031 inches ≈, 0.079 mm). The system is defined so that each gauge step changes area by a constant factor.

- Key Points: AWG gauges have fixed diameters and areas (per ASTM B258). Typical household wiring is AWG 12 or 14, and telephone wiring is often AWG 22–26. As one AWG number rises (thinner wire), the wire’s resistance and current-carrying capacity decrease.

Standard Wire Gauge (SWG)

- Definition: SWG is a British/Imperial standard (BS 3737) for wire and sheet thickness. It is sometimes referred to as the British Standard Wire Gauge. SWG uses gauge numbers (and “/0” for large sizes, e.g., 7/0) to denote specific diameters.

- Size Scale: Like AWG, larger SWG numbers mean thinner wire. For example, SWG 7/0 is 0.500 in (12.70 mm) and SWG 50 is 0.001 in (0.025 mm). The chart is roughly logarithmic (though piecewise-linear in segments).

- Usage: SWG was the British standard of the 19th century. Modern wiring has mostly replaced metric sizing. SWG is no longer an active standard, but some legacy uses persist (e.g., instrument wires, guitar strings). Importantly, SWG gauges are not interchangeable with AWG: they use a different numbering scheme.

IEC Metric Standard (IEC 60228)

- Definition: IEC 60228 is the international standard for cable conductors. It specifies wire sizes by cross-sectional area in square millimeters, not by gauge number.

- Standard Sizes: The IEC list includes common sizes such as 0.5, 0.75, 1, 1.5, 2.5, 4, 6, 10, 16, 25, 35, 50, 70, and 95 mm², as well as very large conductors (up to 2500 mm²). These round numbers accommodate various current loads.

- Why Area Matters: Describing wires by area is convenient because area is proportional to strength and current capacity and inversely proportional to resistance. A larger cross-section can safely carry more current. The IEC metric system is widely used outside North America, Europe, and Asia, where wires are sold by square millimeters (mm²).

Comparing AWG, SWG, and IEC

These three systems all measure wire thickness, but with different units of measurement. AWG and SWG use “gauge” numbers (smaller gauge = larger diameter), while IEC uses metric area. An AWG/SWG chart can list the diameter or area for each gauge. A wire gauge chart helps translate between systems.

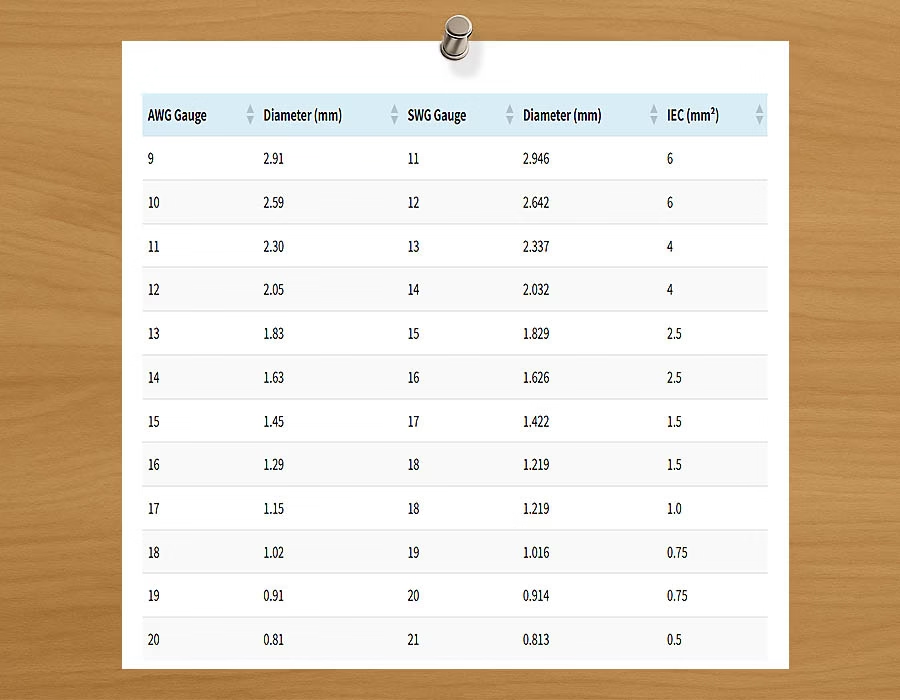

For example, 14 AWG has a diameter of approximately 1.63 mm (≈2.08 mm² area), which is almost the same as that of SWG 16 (≈1.626 mm). Both are slightly smaller than the IEC standard size of 2.5 mm². Similarly, 12 AWG (2.05 mm dia) ≈ 4 mm², close to SWG 14 (2.032 mm dia), matching IEC 4 mm². The following table is a complete cross-reference of AWG 4/0 through 30, SWG, and IEC, compiled from our standard specifications.

| AWG Gauge | Diameter (mm) | SWG Gauge | Diameter (mm) | IEC (mm²) |

|---|---|---|---|---|

| 4/0 | 11.68 | 6/0 | 11.786 | 95 |

| 3/0 | 10.40 | 4/0 | 10.160 | 95 |

| 2/0 | 9.27 | 3/0 | 9.449 | 70 |

| 1/0 | 8.25 | 1/0 | 8.236 | 50 |

| 1 | 7.35 | 1 | 7.620 | 35 |

| 2 | 6.54 | 3 | 6.401 | 35 |

| 3 | 5.83 | 4 | 5.893 | 25 |

| 4 | 5.19 | 5 | 5.385 | 25 |

| 5 | 4.62 | 7 | 4.470 | 16 |

| 6 | 4.12 | 8 | 4.064 | 16 |

| 7 | 3.67 | 9 | 3.658 | 10 |

| 8 | 3.26 | 10 | 3.251 | 10 |

| 9 | 2.91 | 11 | 2.946 | 6 |

| 10 | 2.59 | 12 | 2.642 | 6 |

| 11 | 2.30 | 13 | 2.337 | 4 |

| 12 | 2.05 | 14 | 2.032 | 4 |

| 13 | 1.83 | 15 | 1.829 | 2.5 |

| 14 | 1.63 | 16 | 1.626 | 2.5 |

| 15 | 1.45 | 17 | 1.422 | 1.5 |

| 16 | 1.29 | 18 | 1.219 | 1.5 |

| 17 | 1.15 | 18 | 1.219 | 1.0 |

| 18 | 1.02 | 19 | 1.016 | 0.75 |

| 19 | 0.91 | 20 | 0.914 | 0.75 |

| 20 | 0.81 | 21 | 0.813 | 0.5 |

| 21 | 0.72 | 22 | 0.711 | 0.5 |

| 22 | 0.64 | 23 | 0.610 | 0.5 |

| 23 | 0.57 | 24 | 0.559 | 0.5 |

| 24 | 0.51 | 25 | 0.508 | 0.5 |

| 25 | 0.46 | 26 | 0.457 | 0.5 |

| 26 | 0.41 | 27 | 0.417 | 0.5 |

| 27 | 0.36 | 28 | 0.376 | 0.5 |

| 28 | 0.32 | 30 | 0.315 | 0.5 |

| 29 | 0.29 | 31 | 0.295 | 0.5 |

| 30 | 0.26 | 33 | 0.254 | 0.5 |

Table: AWG ↔ SWG ↔ IEC wire gauge comparisons. Diameters are solid-wire values.

These comparisons show that no gauge number can “match” perfectly across systems; the IEC sizes jump in steps (2.5, 4, 6, 10 mm², etc.), while AWG/SWG give finer gradations. Wire gauge charts or conversion tables help engineers find the nearest equivalent size when working between systems.

Choosing the Right Wire Size

In practice, the wire gauge (or metric size) you choose depends on the current load, voltage drop, temperature, and the specific application. A thicker wire (lower AWG or larger mm²) will handle more current with less heating. Always check the ampacity charts and regulatory codes for safety. Remember that a wire gauge chart is a planning tool, not the only criterion: factors like insulation, environment, and installation also matter.

Manufacturers often provide gauge references for designers and buyers to ensure accurate measurements. For example, Romtronic, with decades of experience, manufactures custom cable assemblies and wire harnesses. We specialize in guiding customers through these standards and selecting the correct wire gauge for industrial and automation applications.

.avif)

Sam Wu is the Marketing Manager at Romtronic, holding a degree in Mechatronics. With 12 years of experience in sales within the electronic wiring harness industry, he manages marketing efforts across Europe. An expert in cable assembly, wiring harnesses, and advanced connectivity solutions, Sam simplifies complex technologies, offering clear, actionable advice to help you confidently navigate your electrical projects.