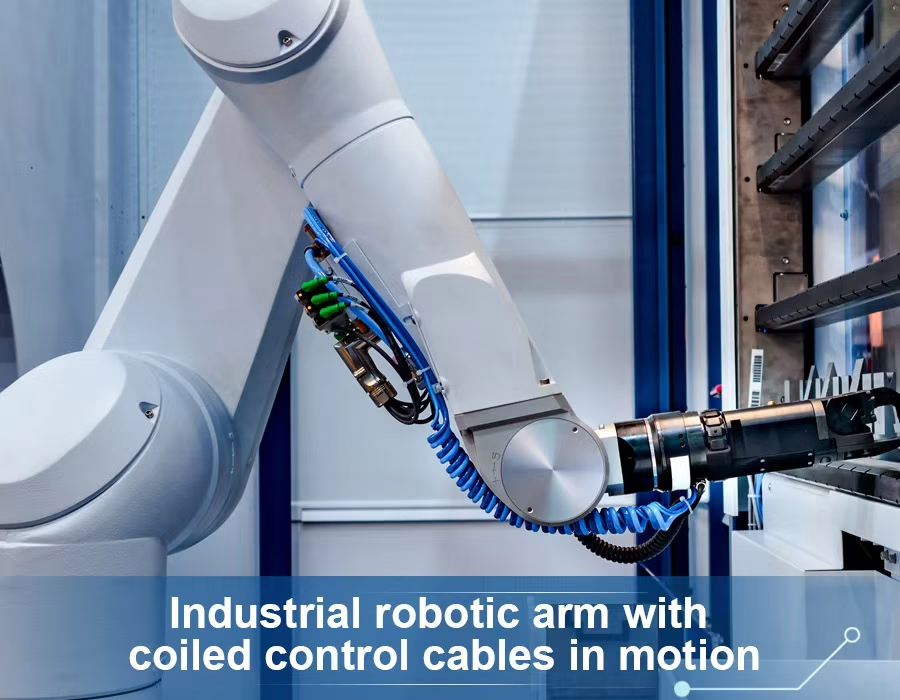

In today’s fast-paced industrial situations, every inch of space and cable connection is critical. Spiral cable assemblies—cables with spring-like, retractable properties—are not only convenient and practical, but they are also designed to resist the rigors of demanding applications.

From factory automation to medical equipment, utilizing the proper custom spiral cable for industrial machinery can significantly enhance equipment performance and durability. Engineers and designers must have a thorough understanding of the technological advantages of spiral cable assemblies to improve system performance.

What Makes Coil Cable Assemblies Different

Unlike straight wires, coiled cables can freely extend and retract, staying out of the way during idle periods. Their exceptional flexibility prevents tangling and breakage, making them ideal for use with mobile equipment or handheld tools.

Key benefits include:

- Space Efficiency: Scalable design keeps cables neatly organized.

- Durability: Withstands thousands of pull cycles.

- Flexibility: Moves with equipment without causing cable fatigue.

- Electromagnetic Shielding: Protects signals from electromagnetic interference.

For more tips on selecting the proper coil cable assembly, check out How to Choose the Right Coil Cable Assembly – Buyer’s Guide.

🔧 Looking for robust and future-ready cable assemblies for smart infrastructure?

Romtronic provides fully customizable wiring harnesses and modular cable assemblies that integrate sensors, fiber optics, and durable enclosures for seamless smart city or industrial deployment.

👉 Contact our engineering team for tailored solutions →

Why Custom Solutions Outperform Off-the-Shelf Options

Pre-made cables perform well under normal conditions but prove challenging to troubleshoot when failures occur. Off-the-shelf solutions may not meet your specific requirements for length, voltage, or motion. This is precisely where custom coiled cable assemblies shine.

A tailored solution ensures:

- Precision fit: Length, pitch, and coil diameter optimized for your layout

- Material Compatibility: PVC, PUR, or TPE jackets tailored to your operating environment

- Electrical Performance: Conductor specifications matched to signal transmission or power load requirements

- Stress Relief & Connectors: Engineered for real-world applications, not just specification sheet compliance

Learn more about the advantages of custom coil cable assemblies in Benefits of Custom Coil Cable Assemblies for Industrial Equipment.

Quick Comparison: Standard vs. Custom Coil Cable

| Feature | Standard Coil Cable | Custom Coil Cable |

|---|---|---|

| Cable Length | Fixed | Adjustable to project specs |

| Jacket Material | Generic PVC | PVC / PUR / TPE / TPU options |

| EMI Shielding | Optional | Integrated or layered |

| Connector Types | Limited | Customizable (USB, M8, DC, etc.) |

| Cycle Life | Moderate | Optimized for motion stress |

| Cost Efficiency | Lower upfront | Higher long-term ROI |

Applications Across Industries

Coil cable assemblies are not universally applicable—they are categorized as follows:

- Medical Devices: Patient monitors, surgical instruments

- Industrial Automation: Robotic arms, CNC machine tools

- Transportation: Truck data links, retractable trailer cables

- Defense & Aerospace: Ruggedized tactical systems

- Consumer Electronics: Charging docks, headphones

Customization is critical, as different environments demand varying requirements for bend endurance, shielding performance, and temperature resistance.

The Engineering Behind Durability

Helical cables withstand tensile stress, torsion, and continuous motion. Engineering features include:

- Tightly wound helical geometry ensures shape memory.

- Multi-strand conductor design effectively prevents breakage.

- Internal filler prevents distortion under load.

- Electromagnetic shielding, achieved through braided or foil layers, ensures signal purity.

💡 Tip: When customizing cables, always specify maximum extension length and rebound force values. These parameters directly influence coil pitch and jacket design.

How Custom Coil Assemblies Reduce Long-Term Costs

Many engineers focus solely on unit cost, but total cost of ownership (TCO) offers a different perspective.

A $3 off-the-shelf cable may fail after 50,000 cycles, while a $10 custom component can last ten times longer. This translates to less downtime, fewer replacements, and higher reliability—especially on production lines.

💡 Ready to optimize your cable layout for dynamic motion?

Romtronic’s engineering team specializes in designing custom coil cable assemblies that balance flexibility, electrical integrity, and long-term reliability.

👉 Request a free design consultation today →

FAQs: Coil Cable Assemblies

A: Polyurethane (PUR) and thermoplastic elastomers (TPE) offer excellent chemical resistance, oil resistance, and abrasion resistance. Polyvinyl chloride (PVC) is suitable for indoor environments.

A: Select cables with braided or foil shielding and a proper grounding configuration.

A: Yes. Many manufacturers provide color-coded jackets or printed logos for easy identification.

A: Typically 2 to 4 weeks, depending on complexity and workload.

Conclusion

Coil cable assemblies may appear simple, but they are precision-engineered components that enhance safety, performance, and system longevity. Custom designs not only meet aesthetic requirements but also solve practical mechanical and electrical challenges in real-world applications.

When dealing with motion, space constraints, or signals sensitive to electromagnetic interference, selecting custom coil cables for industrial equipment is a wise choice that fully unleashes all the advantages of spiral cable assemblies.

.avif)

Sam Wu is the Marketing Manager at Romtronic, holding a degree in Mechatronics. With 12 years of experience in sales within the electronic wiring harness industry, he manages marketing efforts across Europe. An expert in cable assembly, wiring harnesses, and advanced connectivity solutions, Sam simplifies complex technologies, offering clear, actionable advice to help you confidently navigate your electrical projects.