Boat trailer wiring is crucial for safely and efficiently operating your trailer’s lighting system. Boat trailers are subjected to harsh conditions and heavy loads, making their lighting systems prone to failure over time. While apparent damage, like a broken lens, is easy to spot and fix, wiring issues can be more challenging to detect and repair. Sometimes, replacing the entire boat trailer wiring system might be safer and more efficient than troubleshooting.

Selecting the Right Wire Harness for Boat Trailers

Choosing the correct wire harness for a boat trailer is crucial for maintaining the safety and functionality of your boat trailer’s lighting system. Here are some key considerations:

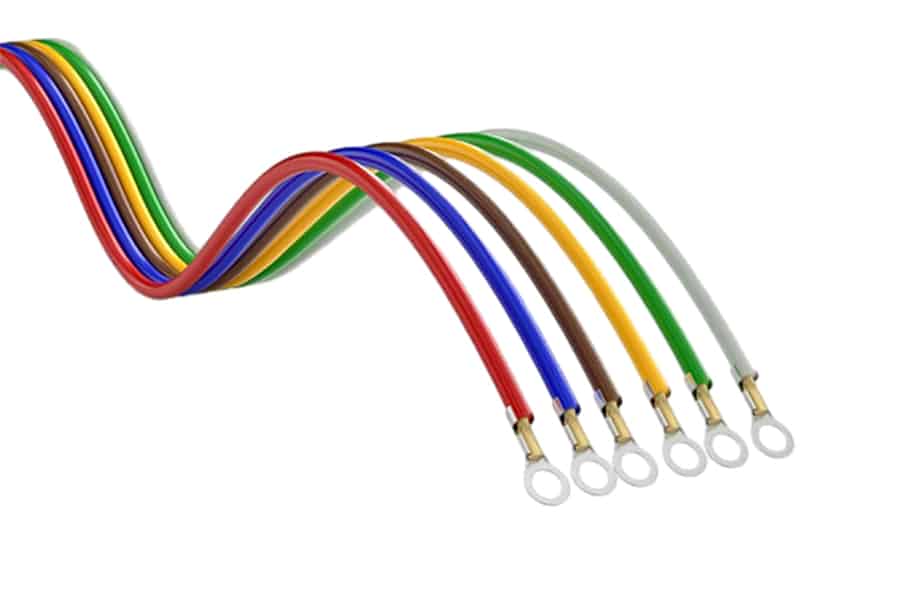

Types of Wire Harnesses for Boat Trailers

- Four-Way Flat Wiring Harness: This harness is ideal for small to medium-sized trailers and consists of four wires: brown (tail lights), yellow (left turn/brake lights), green (right turn/brake lights), and white (ground).

- Five-Way Flat Wiring Harness: This harness features an additional blue wire for electric brakes, making it suitable for trailers equipped with such brakes.

- Six-Way Round Wiring Harness: This harness provides auxiliary power and reverses the light signal pins, making it suitable for larger trailers with additional electrical features.

- Seven-Way RV Blade Wiring Harness: The most comprehensive, supporting electric brakes, auxiliary power, battery charging, and reverse light signals.

Wiring Configuration

- Wishbone Wiring Harness: Splits the running light circuit at the connector, simplifying wiring to the taillights.

- Crossover Wiring Harness: Runs wiring down one side of the trailer and across between the taillights.

Connector Types

- Flat Connectors: Pins line up in a row.

- Round Connectors: Pins are arranged in a circular configuration.

- RV Blade Connectors: Round with rectangular pins, used for more complex wiring needs.

Installation Steps

- Run the Wires: Remove the old wire harness and use it to pull the new wires through the trailer frame. Ensure the harness reaches all lights, including clearance lights on the rear cross member.

- Connect the Lights:

- Running Lights: Use crimp connectors with heat-shrink collars for durability, especially in saltwater environments.

- Brake/Turn Lights: Use heat-shrink tubing to protect connections from corrosion.

- Secure the Wires: Use galvanized wire clips to secure the harness along the trailer frame, ensuring it is tight but not pinched. Leave enough slack at the plug end for easy connection to the towing vehicle.

- Testing: After installation, test all lights by connecting the trailer to the tow vehicle. Ensure all functions (turn signals, brake lights, running lights) are operational.

Maintenance Tips

- Regular Inspections: Check for corrosion, especially in connections and ground points. Clean contacts regularly to prevent signal disruption.

- Protective Measures: Utilize heat-shrink tubing and corrosion-resistant connectors to prolong the lifespan of your boat trailer wire harness.

Troubleshooting Tips

- Light Tester: Use a 4-way light tester to quickly identify issues with tail lights, ground lights, or turn signals.

- Ground Connection: Ensure the ground is connected to a clean, unpainted surface on the chassis. Each light assembly should also have a solid ground connection.

- Battery and Multimeter: Use a battery connected to a female receptacle to isolate problems with the trailer or the towing vehicle. A multimeter can help narrow down issues further.

Complete Rewiring of Boat Trailer Lights

If the lighting system on your boat trailer is old and there are several non-functioning lights, it’s likely time for a complete rewire.

- Choosing the Right Plug: Select the appropriate plug based on your needs, whether it is a flat plug or a round plug. The color coding is the same for both.

- Running New Wiring: Remove the old wires, using them to pull the new wires through the tubes if applicable. Otherwise, clip the old zip ties and secure the new wiring with zip ties.

- Connecting the Lights: Follow the manufacturer’s instructions to match wire colors and connect the new lights. Use solder and heat-shrink tubing for durable, waterproof connections.

- Securing the Wiring: Use a flexible plastic conduit to protect the wires from chafing and ensure they are neatly tucked out of the way.

Conclusion

Correctly wiring your boat trailer is essential for safe and legal towing. Selecting the correct wire harness and maintaining it diligently ensures that your trailer lights function correctly, allowing you to enjoy your boating adventures without worry. Consulting with a marine equipment expert or a local dealer is always advisable for addressing any doubts or specialized needs.

For professional help, consider using a repair service that can handle all aspects of boat trailer maintenance, from wiring to wheel bearings and brakes.

For customized Boat Trailer Wiring, contact Romtronic for a one-stop shop and reliable products that meet safety standards.

.avif)

Sam Wu is the Marketing Manager at Romtronic, holding a degree in Mechatronics. With 12 years of experience in sales within the electronic wiring harness industry, he manages marketing efforts across Europe. An expert in cable assembly, wiring harnesses, and advanced connectivity solutions, Sam simplifies complex technologies, offering clear, actionable advice to help you confidently navigate your electrical projects.