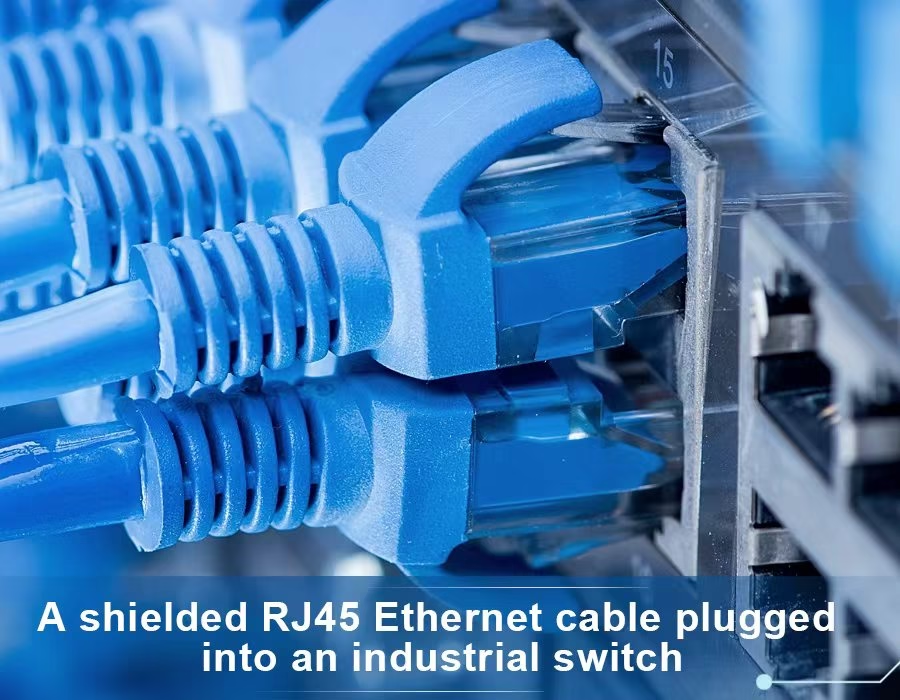

Ordinary office network cables often malfunction in demanding environments, such as factories, data centers, or industrial Ethernet networks. To maintain data flow in noisy conditions, engineers rely on shielded RJ45 (STP) cables with intense strain relief and complete 360° metal shields.

These cables are designed to withstand severe circumstances, manage vibration, and block off EMI/RFI. (In comparison, USB cables are typically used for short device-to-device connections rather than lengthy network routes.) STP, 360° shielding, strain relief, and when to choose an Ethernet (RJ45) cable over a USB cable will all be covered in this article.

Industrial Ethernet cables are frequently ruggedized and insulated. Electrical noise from motors, drives, welders, and power lines is a continual problem for industrial networks (factory automation, process control, etc.). A shielded RJ45 connector attaches to the foil/braid and drain wire of the cable and is metal-clad, functioning as a Faraday cage.

By shunting interference to ground, this “360° shield” around the connector keeps the twisted-pair data wires from becoming corrupted. By connecting the cable’s shield all the way through (via the plug’s grounding tab), stray RF noise is blocked before it may cause packet mistakes. To put it briefly, a fully shielded STP cable ensures signal integrity in challenging environments by significantly reducing EMI/RFI and crosstalk.

Why Shielding Matters (EMI in Industrial Networks)

Factories and data centers are EMI minefields: power lines, arc welders, variable-frequency drives, and large motors all produce broadband electrical noise, which a bare (UTP) cable can pick up like an antenna, causing bit errors or dropped links. In contrast, the metal sheath of a shielded cable completely encloses the wires. Because the metal shell of the connector is bonded to chassis ground, electrical interference is literally wrapped up and dissipated without causing any harm.

This implies that shielded (STP/FTP) cables can be installed thousands of feet away or in proximity to power equipment without experiencing any issues. To maintain the shield’s continuity, the plug’s metal housing must be connected to the cable’s foil drain wire. When properly installed, 360° shielded cables function as miniature Faraday cages for every link, which is essential for industrial Ethernet applications where reliability is crucial.

STP Termination and 360° Shielding

Terminating an STP RJ45 plug is more complicated than terminating a standard UTP plug. The shielded connector features a metal cage surrounding the contacts and often includes an external ground tab. To terminate, fold back the foil and braid of the cable, insert the wires, and crimp the ground tab of the shield onto the drain wire. This connects the entire shield of the cable to the connector body, giving the connector 360° coverage.

For instance, to satisfy high-speed data requirements, TE Connectivity’s industrial RJ45 series has a MIL-spec metal casing with “complete 360-degree EMC and mechanical protection.” To put it simply, the plug is designed to be metal-to-metal, eliminating electromagnetic interference at every angle.

Shielded plugs must be crimped to the cable’s drain to ensure the shield remains continuous and uninterrupted. This significantly lowers crosstalk and EMI/RFI in noisy settings. You completely lose that advantage if you combine a shielded cable with an unshielded plug, or vice versa.

Notice the metal connector housing – this is part of the 360° shield system. This thick shielding is why industrial RJ45 cables can transmit gigabits reliably even under electrical stress. Additionally, because the additional metal braid consumes up space, STP cables are usually heavier and slightly stiffer than regular residential cables. However, on manufacturing floors or any other high-EMI location, such a trade-off is necessary.

Strain Relief: Protecting the Connection

Strain relief is another essential component of industrial Ethernet cables. The cable jacket is held in place at the connector by this flexible boot or casing. Its job is to absorb pulls, bends, and tugs so the fragile plug termination isn’t damaged. Boots are frequently snapped on after the plug or molded over it in RJ45 setups. Stated differently, the boot hinders the yanking or flexing of the metal contacts within the plug.

Strain-relieving boots also enforce proper bend radius. They prevent users from making a tight bend at the connector, which is a common source of failure, by extending the curve from the plug’s end onto the cable. When the cable is pulled or kinked, a good boot flexes or slides rather than applying force to the solder joints or wires.

For example, some rugged RJ45 plugs feature built-in boots or threaded collars that secure the cable in place, ensuring the connector remains sealed and grounded even under vibration. The combination of a 360° EMI shield and intense strain relief creates a robust connection that won’t fail from a stray tug or electromagnetic blast. Metal strain-relief shells or integrated rubber gaskets (to meet IP ratings) are frequently seen in industrial models.

RJ45 (Ethernet) vs. USB Cable: Use Cases & Selection

Does industrial networking support USB? Usually not; USB and RJ45 have separate purposes. Consider USB as the device-to-host connection and Ethernet (RJ45) as the wired network backbone. Although USB cables are excellent for charging devices and connecting peripherals like printers, cameras, keyboards, and hard drives, their length is only a few meters, and they are not designed to be daisy-chained in a plant Ethernet ring.

Use Ethernet if you require a fast and consistent internet or network connection across a location, but use USB when connecting individual devices or transferring files/charging. In other words, an RJ45 Cat6 cable can join two switches 100 meters apart at gigabit speeds, whereas a USB cable couldn’t stretch that far or support that topology.

Despite this, USB can only reach ~5–10 meters without repeaters, but USB 3.x can reach greater top speeds on short runs (up to 20+ Gbps). Typically, industrial Ethernet (Cat6A/STP) operates at 10Gbps for 100 meters. USB cables are not designed for EMI immunity; they are generally unshielded or have only a foil/twisted pair shield.

In an industrial setting, for example, when integrating sensors or cameras with a PLC, STP Ethernet cables are used because of their robust connectors, noise immunity, and distance. USB is not the network backbone, although it may still be utilized for tasks such as adding a peripheral to a controller or locally programming a device.

| Feature | Industrial RJ45/STP Cable | USB Cable |

|---|---|---|

| Use-Case | Ethernet networking (LAN, industrial bus) | Device/peripheral connections |

| Data Rates | 1–10+ Gbps (Cat6A/STP) | 480 Mbps (USB2) to 5–20 Gbps (USB3) |

| Max Length | Up to 100 meters (copper) | 5–10 meters (without boosters) |

| Shielding | Foil/braid (360° metal connector) for EMI | Minimal (twisted pair, maybe braid) |

| Typical Connectors | RJ45 (8P8C) | USB-A/B/C, micro, etc. |

| Use Environment | Offices, data centers, industrial plants | PCs, instruments, devices, phones |

| Strain Relief | Often built-in boots or glands | Usually molded rubber boots |

This brief table outlines the benefits of using USB cables for direct device connections and Ethernet (RJ45 STP) cables for network and industrial applications. Although they serve different purposes, both kinds of cables may be found in a facility.

FAQs

- What is STP (Shielded Twisted Pair)?

STP cables have an additional metal layer (foil and/or braid) around the twisted wire pairs. This shield reduces electromagnetic interference. A shielded RJ45 plug pairs with STP cable and has a metal shell bonded to the cable shield. - What does “360° shield” mean?

In actuality, 360° shielded jacks or plugs enclose the entire port and plug in metal that connects to the cable’s shield, creating a Faraday cage to limit interference. This indicates that the connector’s housing is entirely covered in metal. - Why use strain-relief boots on RJ45 plugs?

To prevent damage to the termination, the boot absorbs bending and pulling stress at the cable plug. It prevents the cable from coming loose or flexing excessively. Boots “provide strain relief to ease pressure on the connector termination” and stabilize performance, according to trueCABLE. - When should I use a USB connection instead of an Ethernet connection?

Use a USB when connecting peripherals or transferring data to/from a single device (e.g., a camera to a PC, or charging a phone). Use an Ethernet (RJ45) cable when setting up a network or linking computers/network gear over a distance. While USB is used for point-to-point device links, Ethernet cables can travel much farther and withstand industrial noise. - Can I plug a shielded cable into an unshielded jack?

You shouldn’t because the ground continuity is broken when shielded cable and unshielded connections are used. The connector must be crimped to the cable’s drain wire, and both the cable and connector must support shielding to provide complete EMI protection.

Choosing the right cable means matching the cable type, connectors, and features to your scenario. In industrial automation or data centers, that often means shielded RJ45-to-RJ45 assemblies with 360° metal shields and solid strain relief boots.

But whenever you need a USB (for devices or short links), pick the appropriate USB type and quality. The key is understanding each cable’s role: Ethernet cables build your network, and USB cables link individual devices.

.avif)

Sam Wu is the Marketing Manager at Romtronic, holding a degree in Mechatronics. With 12 years of experience in sales within the electronic wiring harness industry, he manages marketing efforts across Europe. An expert in cable assembly, wiring harnesses, and advanced connectivity solutions, Sam simplifies complex technologies, offering clear, actionable advice to help you confidently navigate your electrical projects.