Quality Control

At Romtronic, quality control is more than just a step in the process—it’s the foundation of everything we do. From the initial design phase to the final product, we integrate rigorous testing and meticulous standards to ensure that every cable and wire harness we produce meets the highest standards of precision, reliability, and durability. Our commitment to excellence has allowed us to achieve an industry-leading defect rate of just 0.1%, setting a new benchmark for quality.

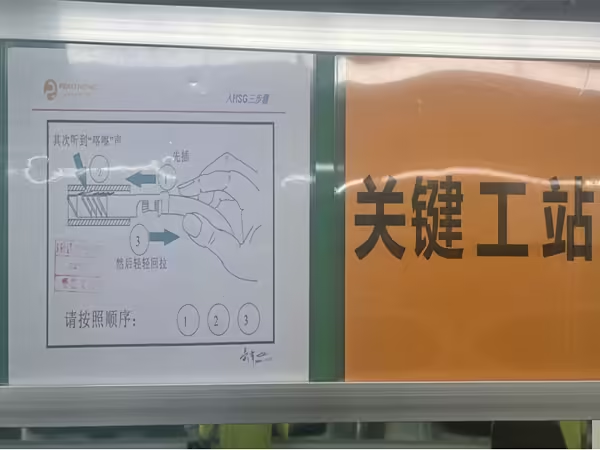

Key Control Processes

We focus on precision throughout our manufacturing process. Romtronic utilizes high-precision automated terminal crimping equipment equipped with real-time pressure monitoring sensors to ensure top-tier quality. Each critical step is supported by high-definition CCD detection, ensuring that every detail is thoroughly checked and rechecked. Our standard work practices guide each key process, ensuring every product we create is consistent, reliable, and of the highest quality.

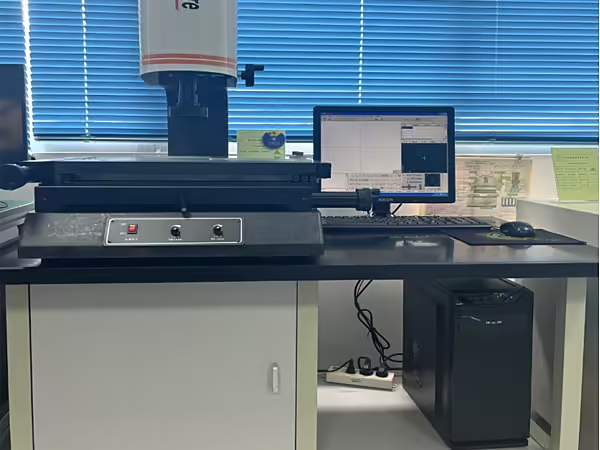

Testing equipment

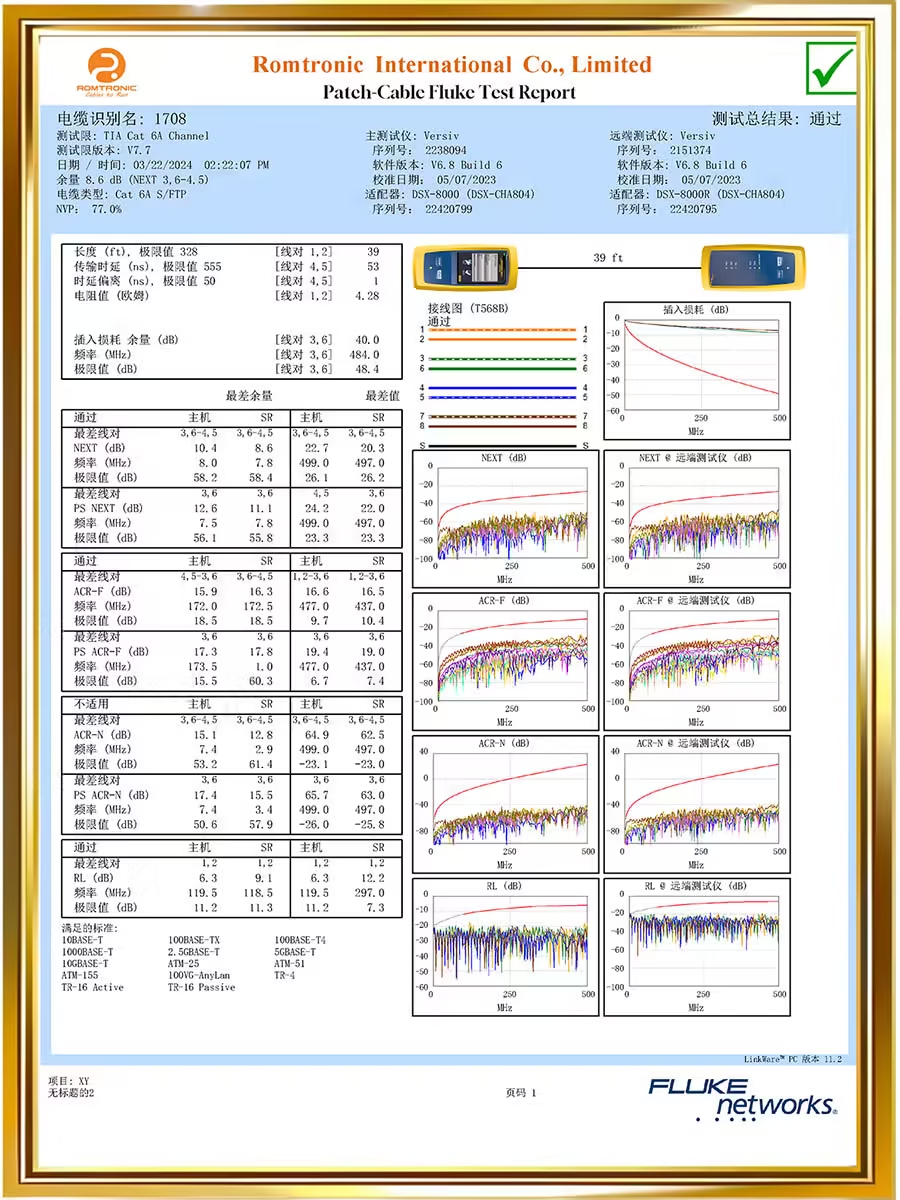

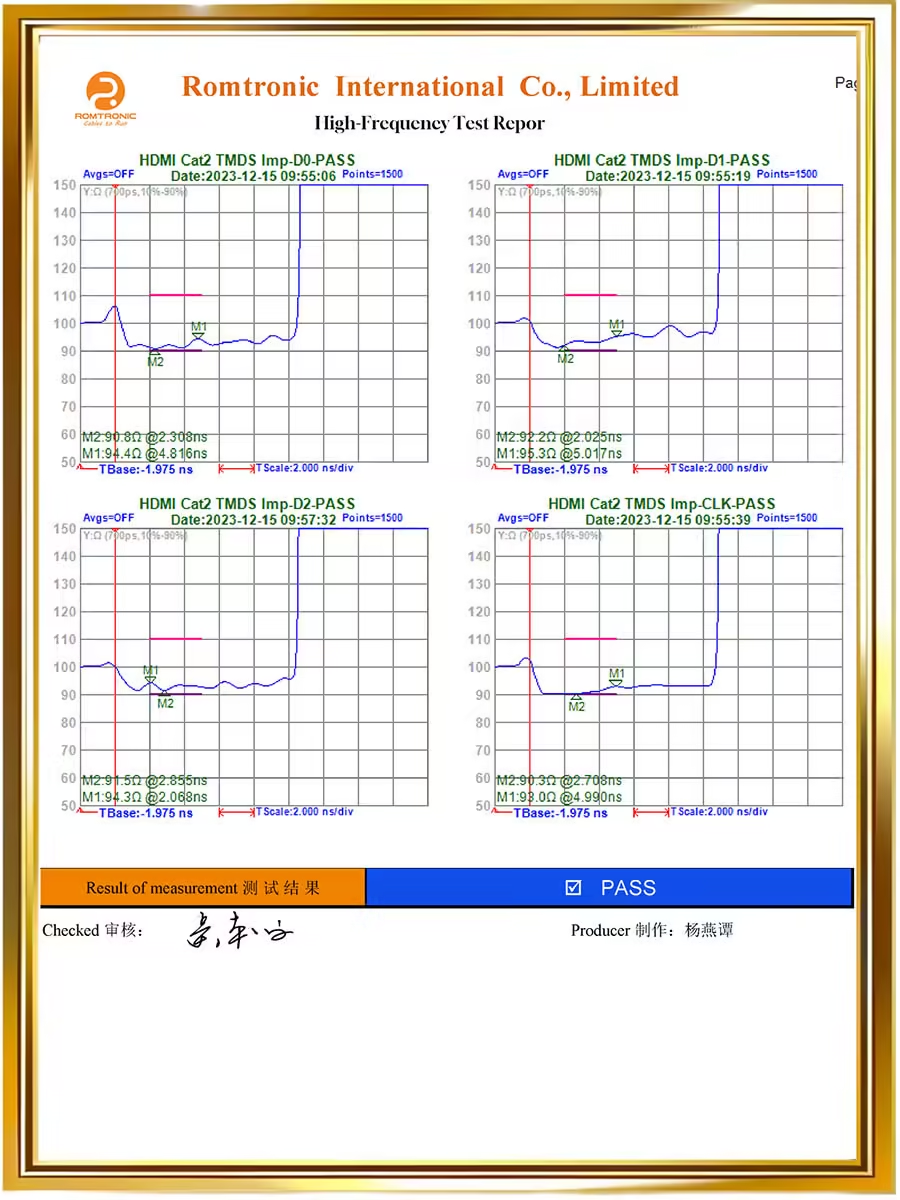

At Romtronic, we use a wide range of advanced testing equipment to ensure our cables and wire harnesses meet the highest quality standards. Our tools, such as 4 K-8 K test monitors, FLUKE network analyzers, and TDR network analyzers, are essential for verifying the performance and durability of our products. With cable bending testers, comprehensive testers, and salt spray testers, we ensure every product can handle the most challenging conditions and is built to last.

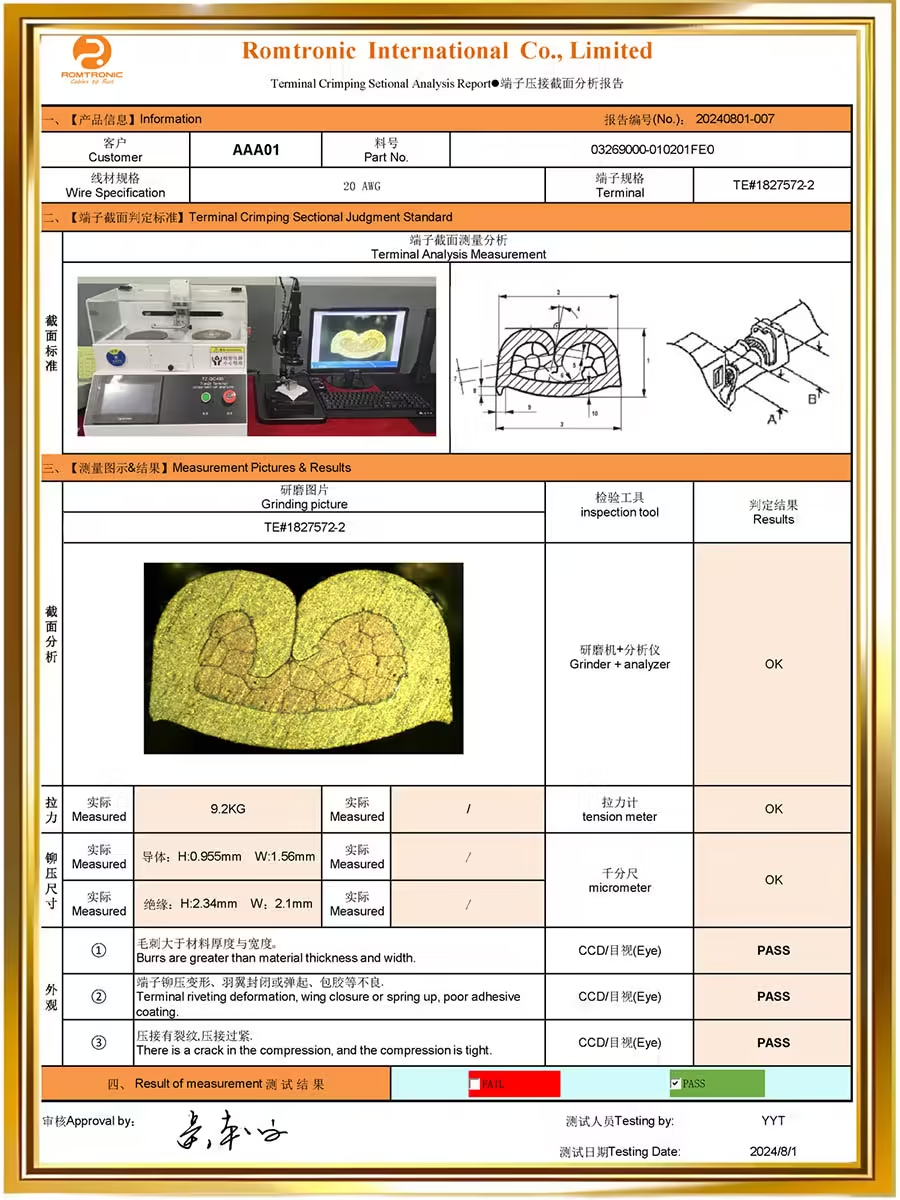

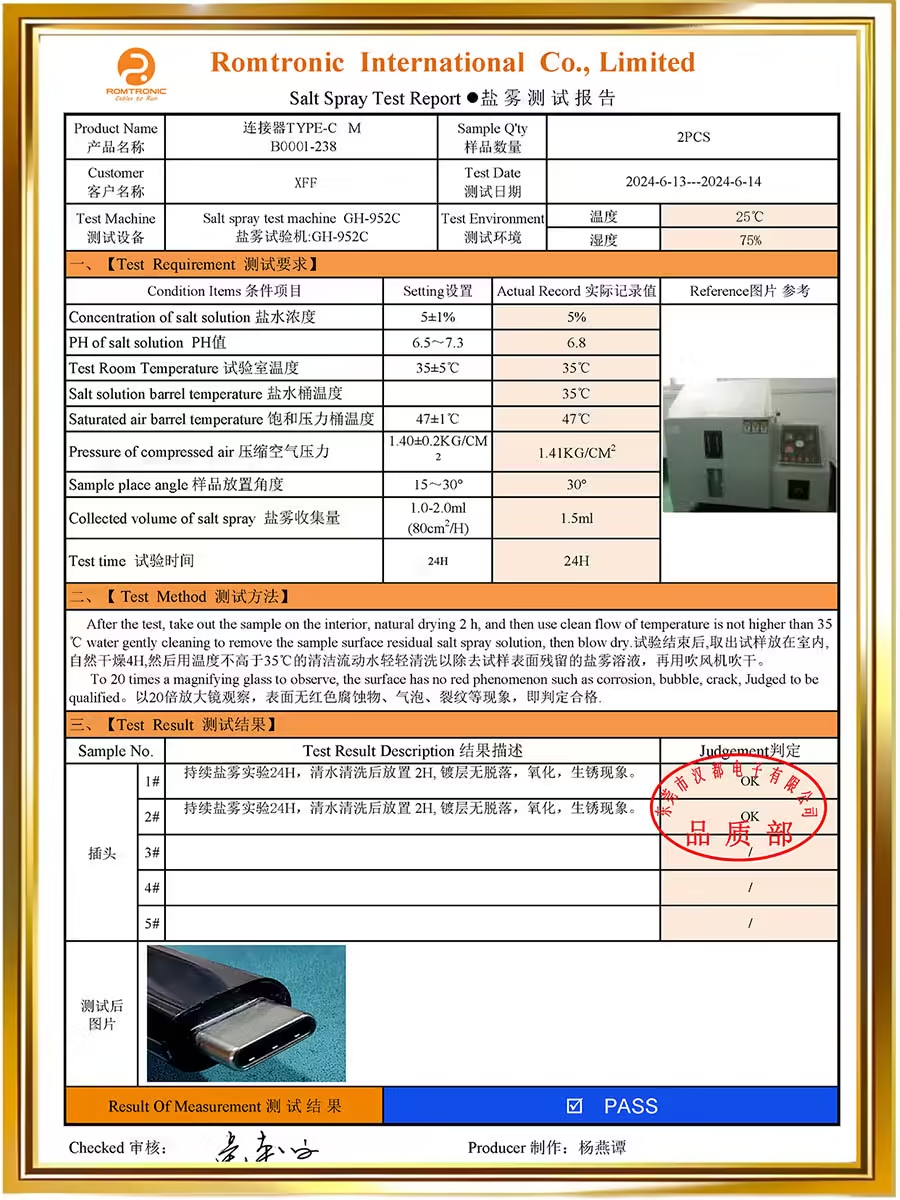

Testing Report

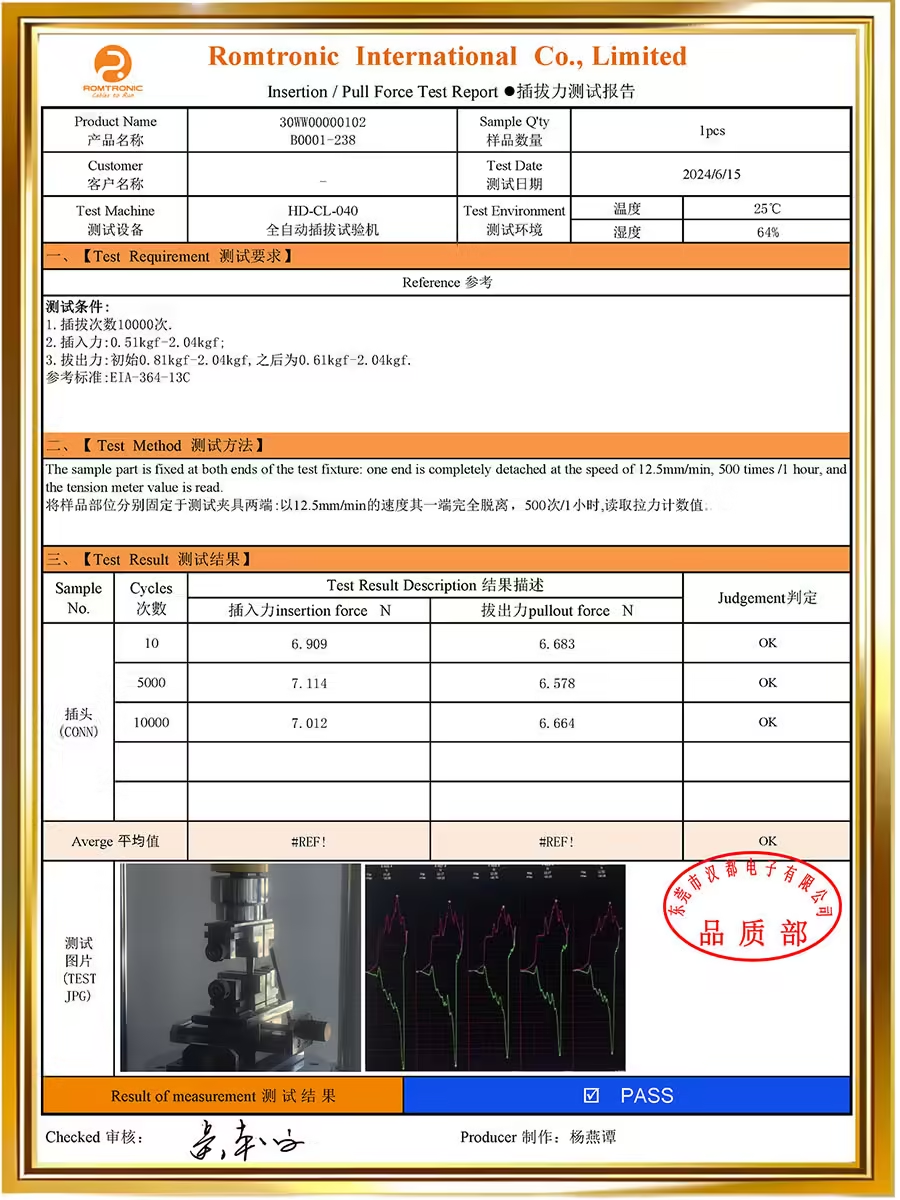

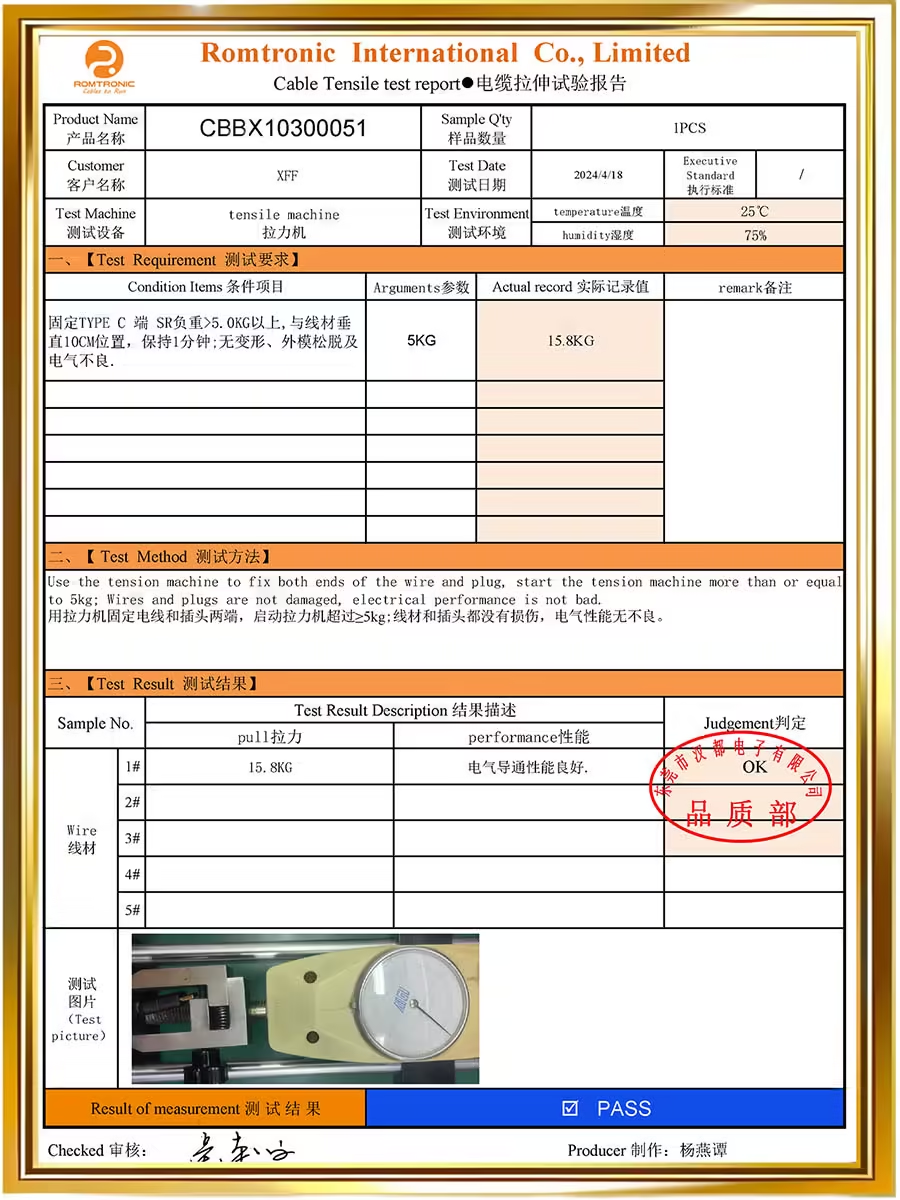

Our dedication to quality is evident in the extensive testing and detailed reporting we provide. We ensure every product is thoroughly vetted, from Cable Bending Test Reports to Cable Tensile and High-Frequency Test Reports. We also provide in-depth analyses like the Terminal Crimping Sectional Analysis Report and Patch-Cable Fluke Test Report. At Romtronic, we’re committed to delivering top-notch products that meet and exceed your expectations.