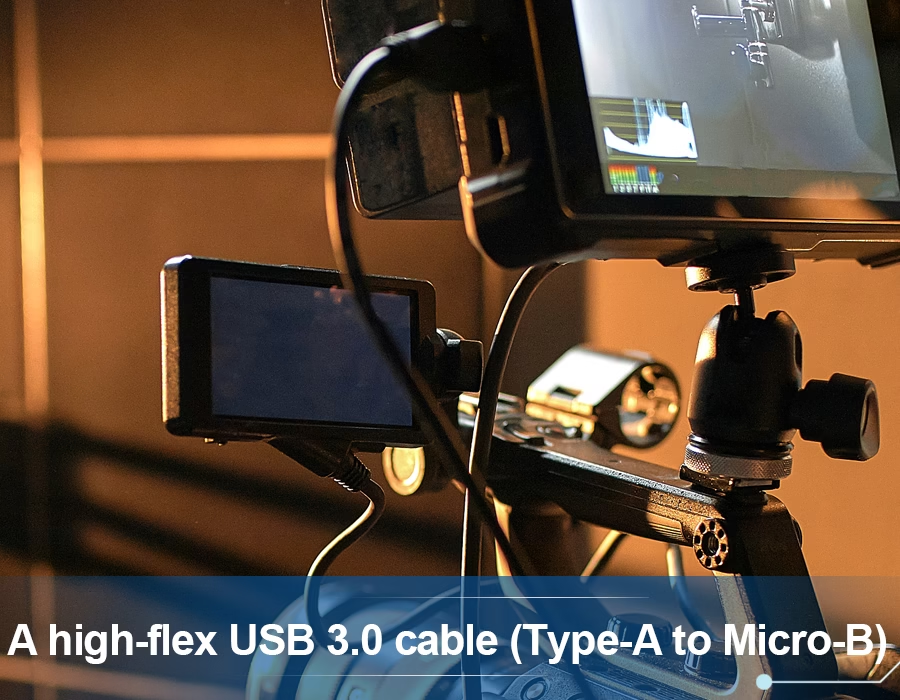

In modern factories and automated lines, USB 3.0 cables often reside in drag chains (also known as cable carriers or energy chains), where they bend and flex constantly. Standard USB cables won’t survive long under those conditions. High-flex, industrial-grade USB-A to USB Micro-B cables are built to endure millions of bends. They utilize fine-stranded conductors, robust jackets, and secure connectors to ensure data flows reliably in motion.

For example, specialized cables are rated for 5–12 million flex cycles in drag-chain setups. These cables feature thicker conductors (e.g., 24 AWG for power, 28 AWG for data) and additional shielding (foil + braid) to support SuperSpeed 5 Gbps transfers, even when in motion.

Unlike cheap “office” cables, these cables use durable jackets (PUR or high-grade PVC) that resist oil, coolants, and abrasion. Their jackets and inserts are engineered for repeated bending; many spec sheets require a dynamic minimum bend radius of around 10–12 times the cable diameter (for example, ~48 mm for a 5.5 mm cable). Exceeding that can break fine wires and ruin the signal. High-flex cables often carry UL/VW-1 flame ratings and are RoHS-compliant for safety and industrial standards.

The connectors are also rugged: Micro-B plugs commonly include locking screws or thumbscrews (M2 threads) to prevent vibration from loosening them. When choosing a cable, select one explicitly labeled for continuous-motion or drag-chain use.

Why Drag-Chain Cables Matter

Imagine a standard USB cable running back and forth on a moving arm hundreds of times a day – it would quickly fray or break. Drag-chain-rated wires are designed for constant flexing. They’re built “for continuous motion” and have tested life spans of millions of cycles. In practice, this means you can run an industrial USB camera or robot without daily failures. The drag chain (cable carrier) itself shields cables against cuts and impact, reducing wear.

In fact, drag-chain setups significantly enhance safety and reliability by keeping cables organized and protected, thereby preventing electrical faults and downtime. When you use the right cable and chain, machinery uptime increases and maintenance costs decrease.

High-Flex Cable Construction

High-flex, industrial-grade USB-A to USB Micro-B cables are designed to withstand millions of bends, utilizing fine-stranded conductors, robust jackets, and secure connectors to ensure reliable data transmission in motion. In modern factories and automation lines, USB 3.0 cables are frequently found in drag chains (also known as cable carriers or energy chains), where they bend and flex constantly. Standard USB cables are not suitable for such environments.

Unlike cheap “office” cables, these cables have tough jackets (PUR or high-grade PVC) that can withstand oil, coolants, and abrasions. Their jackets and inserts are designed for repetitive bending; many spec sheets demand a dynamic minimum bend radius of about 10-12× the cable diameter (for example, ~48 mm radius for a 5.5 mm cable). Exceeding this limit can damage thin wires and disrupt the signal.

High-flex cables often have UL/VW-1 flame ratings and are RoHS compliant, meeting safety and industrial standards. The connectors are also robust. Locking screws or thumbscrews (M2 threads) are commonly used on Micro-B plugs to prevent vibration from loosening them. When selecting a cable, choose one that is clearly labeled for continuous-motion or drag-chain application.

🛠 Looking for high-flex industrial USB cables that withstand millions of cycles?

Romtronic offers drag-chain rated USB 3.0 Type-A to Micro-B cables with reinforced jackets, screw-lock connectors, and proven continuous-motion performance.

👉 Request a free sample evaluation today →

Installation Best Practices

Even the best cable requires proper care during installation and use. Here are key drag-chain tips:

- Correct Length & Slack: Leaving around 10% excess cable length beyond the straight path length allows the cable to travel freely in the chain without tension. Too little slack might overstress the cable, while too much slack can result in loops or kinking.

- Secure at Both Ends: Anchor the cable at both the fixed and moving ends of the drag chain. Clamp one end firmly to the equipment frame and let the moving end float, allowing the chain to carry the motion rather than the cable’s connectors. Use mild clamps or tie-wraps that won’t cut into the jacket.

- Maintain Bend Radius: Ensure that the chain radius is never smaller than the cable’s minimum bend radius (typically 10-15× OD). Routing across any curves in the chain should adhere to this constraint. A too-sharp bend can break data pairs or drain lines inside.

- Avoid Twists and Overlaps: Lay each cable straight in its compartment—no twisting or crossing inside the chain. Tangled or overlapping cables grind against each other, creating heat and wear. Use separators or dividers to keep multiple wires away.

- Prevent Abrasion: Consider using additional protection if the surroundings contain dirt, chemical spray, or sharp edges. Some installers use drag chains inside slotted conduit or abrasion-resistant jackets to protect the cable. The drag chain provides protection, but in foundry or washdown applications, an outside conduit can be helpful.

Following these instructions protects cables from “chafing out” prematurely. Also, remember to follow any manufacturer’s specific requirements for the cable model in question, as each may have its own unique specifications. In practice, installers frequently design and lay out the cable route before powering up.

Maintenance and Lifespan

Even the most flexible cables do not endure forever. Create a maintenance routine and inspect your USB cable regularly for cuts, pinches, or damaged outer armor. Check the chain path for any snag points. Also, ensure that the connectors and locking screws are snugly in place. Replace the cable if you notice inner wires poking out or if the USB link displays excessive error rates. Some systems include EMI shielding that might decay, so look for missing braid around the ends.

Even if the drag-chain cables appear to be in good condition, it is advisable to replace them after a specified amount of time or a certain number of cycles. (Some facilities store spares for annual swaps.) Swapping a wire is far easier than diagnosing random errors in a vision system throughout the shift. When re-installing a new cable, leave some slack and route it cleanly. A high-flex cable may withstand millions of bends over its lifetime, but any installation error or environmental hazard can shorten that time.

Keeping the system dust-free and preventing fluids from coming into contact with the connectors will also help extend its life. In dusty environments, clean the drag chain and cables regularly to prevent damage. Pur-flex jackets (made of polyurethane) are used by some engineers in exceptionally demanding situations to enhance oil/chemical resistance.

⚡ Need a tailored USB 3.0 cable solution for your automation project?

From lab prototypes to full-scale industrial deployments, Romtronic provides OEM/ODM customization—covering conductor size, shielding, jackets, and connector locking systems.

👉 Contact our engineering team for a custom quote →

Conclusion

You can avoid irritating downtime by using a high-flex USB 3.0 Type-A to Micro-B cable and inserting it carefully. The correct cable, fine-stranded, multi-shielded, and securely fastened at both ends, will withstand thousands of moves in a drag chain. Allow slack (~10%), adhere to the bend radius, and keep the cable straight and untangled in the carrier. When users adhere to these recommended practices, their industrial cameras and machines remain linked and reliable.

In summary, treat the USB cable as a crucial component of your automation hardware: properly install it, inspect it frequently, and it will serve your system reliably for years.

.avif)

Sam Wu is the Marketing Manager at Romtronic, holding a degree in Mechatronics. With 12 years of experience in sales within the electronic wiring harness industry, he manages marketing efforts across Europe. An expert in cable assembly, wiring harnesses, and advanced connectivity solutions, Sam simplifies complex technologies, offering clear, actionable advice to help you confidently navigate your electrical projects.