LEMO cables are high-performance connection solutions that are widely used in industries where reliability is of utmost importance. LEMO connectors, with their signature push-pull locking mechanism, provide secure and repeatable connections under pressure. They are indispensable behind-the-scenes pillars in critical systems, ranging from medical diagnostics to avionics.

Key Industries and Use Cases

Medical Applications

LEMO cables ensure signal integrity and patient safety when connecting medical imaging and diagnostic equipment. Their biocompatibility and sterilization resistance make them ideal for:

- MRI, CT, and ultrasound probes

- Electrocardiography (ECG/EKG) and patient monitoring systems

- Endoscopic video transmission

Products comply with ISO 13485 standards, ensuring traceability and safety.

Romtronic Example: Romtronic’s ISO-certified medical components—such as 19-pin LEMO-to-DVI or LEMO-to-HDMI cables—deliver low-noise, electromagnetically shielded operation for surgical imaging systems.

Aerospace & Defense

LEMO M Series connectors are specifically designed to withstand high temperatures, vibration, and high-altitude environments. Their lightweight yet rugged construction ensures reliable performance in aircraft, unmanned aerial vehicles, and satellite systems.

- Avionics and Navigation Systems

- Radar and Telemetry Equipment

- Space Communication Modules

Romtronic Solution: Romtronic manufactures military-grade cable assemblies incorporating LEMO M Series connectors for avionics and defense applications. To meet aerospace standards, each cable undergoes vibration, salt-spray, and insulation-resistance testing.

Broadcast & Video

For broadcast engineers, LEMO is synonymous with field reliability. The SMPTE 3K.93C hybrid fiber assembly has become the industry standard for HD and 4K cameras.

- This assembly integrates control signals, power, and fiber optics into a single cable.

- Field-ready and waterproof (IP68-rated)

Romtronic Offering: Custom SMPTE 3K.93C camera cables compliant with ARIB/SMPTE standards for film production, live sports events, and OB van applications. Romtronic employs gold-plated connectors and reinforced strain relief to ensure zero transmission loss.

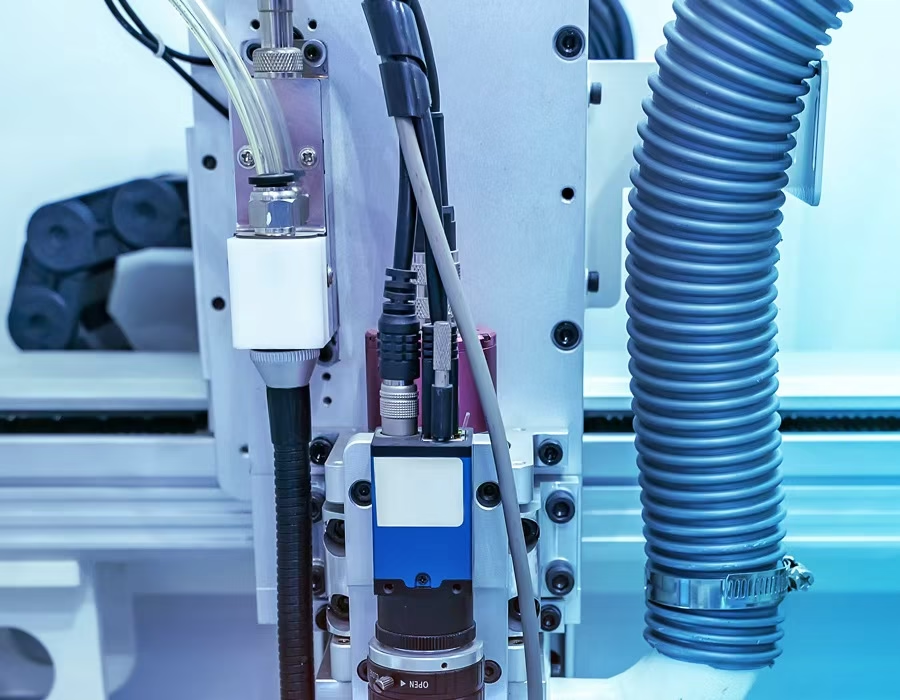

Robotics & Industrial Automation

Robotic systems require flexibility and high uptime. LEMO’s push-pull connectors enable rapid maintenance without compromising performance.

- Industrial robots, actuators, and sensors.

- Factory automation and control panels.

- Vision systems and mobile robots.

Romtronic Fit: Romtronic’s hybrid LEMO cable assemblies integrate power supply, encoder feedback, and pneumatic lines. Components are engineered for repetitive motion cycles and environmental resilience, effectively reducing downtime and maintenance costs.

Telecom & Test Equipment

Precision data transmission is critical in telecommunications and laboratory environments. LEMO connectors provide low-loss, shielded connections for high-speed signals.

- Fiber Optic Test Instruments

- RF Communication Systems

- Data Center Patch Cords and Network Monitoring

Romtronic Example: Romtronic uses LEMO 00 and 1K series connectors to create fiber-optic/coaxial combination assemblies for 50Ω or 75Ω telecom equipment. Romtronic’s fiber-optic terminations undergo sub-micron-precision testing to ensure maximum bandwidth with minimal insertion loss.

Why LEMO Stands Out

| Feature | Advantage |

|---|---|

| Push-pull design | Fast, tool-free locking and release |

| Hybrid contact mix | Power, signal, fiber, or fluids in one unit |

| Superior shielding | Excellent EMI/RFI resistance |

| Modular sizes | Fits diverse voltage and data needs |

| Rugged construction | IP68 and MIL/ISO certified builds |

Romtronic’s Advantage: Beyond standard LEMO configurations, Romtronic offers custom overmolding, cable routing, and materials engineered explicitly for medical, aerospace, and industrial applications. Each component undergoes rigorous testing for conductivity, insulation integrity, and mechanical integrity.

FAQs

A: Primarily, yes. LEMO’s precision engineering focuses on industries demanding extreme reliability, such as medical imaging, aerospace, and professional video. However, Romtronic can also adapt these connectors for mid-range automation and test systems.

A: The Universal (B Series), Heavy-Duty (M Series), and SMPTE 3K.93C (broadcast hybrid) applications are most widely used—components manufactured by Romtronic cover all three categories.

A: Absolutely. Romtronic handles the entire process in-house, including design, procurement, overmolding, and functional testing. We can provide sterile, IP68-rated, or hybrid LEMO cables tailored to your specifications.

A: Absolutely. Romtronic handles the entire process in-house, including design, procurement, overmolding, and functional testing. We can provide sterile, IP68-rated, or hybrid LEMO cables tailored to your specifications.

LEMO cables are not merely transmission media—they embody a performance commitment. From emergency rooms to space orbits, they ensure stable signal transmission and continuous system operation. Backed by Romtronic’s manufacturing expertise, each LEMO assembly becomes a trusted link between innovation and implementation.

Below are the LEMO cables customized by Romtromic for its customers.

.avif)

Sam Wu is the Marketing Manager at Romtronic, holding a degree in Mechatronics. With 12 years of experience in sales within the electronic wiring harness industry, he manages marketing efforts across Europe. An expert in cable assembly, wiring harnesses, and advanced connectivity solutions, Sam simplifies complex technologies, offering clear, actionable advice to help you confidently navigate your electrical projects.