Many factors contribute to the total cost of a custom cable assembly, including: raw materials, the complexity of the design, the manufacturing methods used to build the cable, the desired finish quality (regardless of the production method), and, finally, the number of cables ordered.

Engineers and procurement teams can use this information to help determine how to balance performance, reliability, and cost; therefore, minimising any potential long-term risks that may not have been obvious at the beginning of the project.

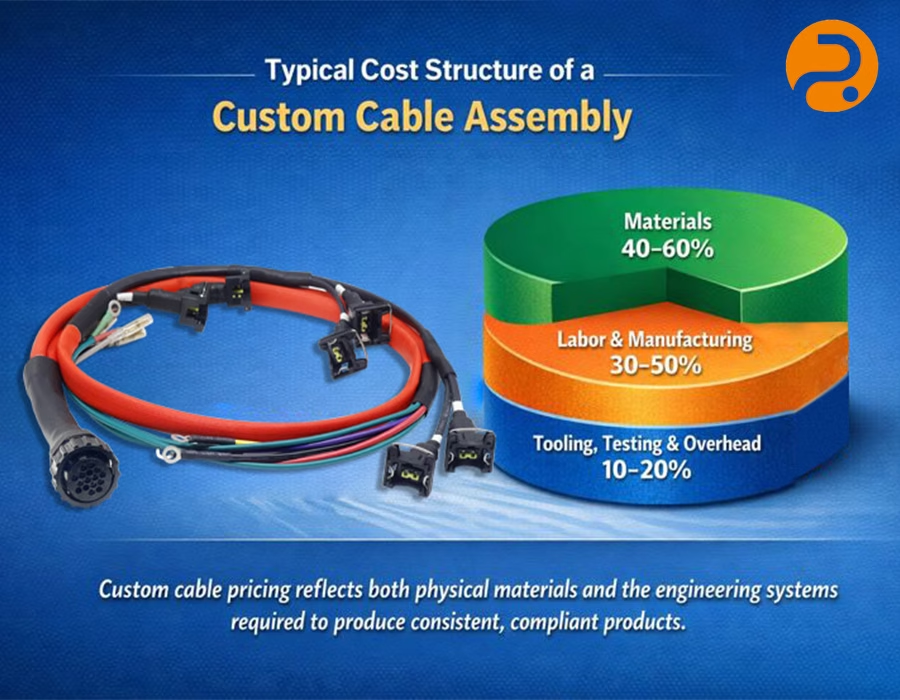

Typical Cost Breakdown of a Custom Cable Assembly

While every project is unique, most professional custom cable assemblies follow a similar structure:

- Materials: 40–60%

- Labor & Manufacturing: 30–50%

- Tooling, Testing & Overhead: 10–20%

This breakdown highlights a key reality: labor, engineering input, and quality systems often influence pricing just as much as the cable itself.

1. Material Choices: The Primary Cost Driver

The primary determinant of the price of custom cables is the materials used in their manufacture.

Conductors for use with custom cables may include bare copper and tinned copper and are often plated with silver for use in extreme temperature and corrosive environments, as well as high-frequency applications. The use of larger wire gauges and/or special alloys for custom cable manufacture will increase both the performance and the cost of these cables.

Insulation material and jacket construction are two other significant factors that influence the cost of custom cables. Most standard PVC-insulated wires are used in many applications; however, the materials used for custom cables include PTFE, silicone, fluoropolymers, polyurethane, and thermoplastic elastomer (TPE), which offer greater temperature resistance, flexibility, and chemical resistance at a higher price than PVC.

Another major cost factor is the cable shielding structure. Cabling that is not shielded or that is shielded solely with foil is typically low cost; however, braided or multilayer shielding provides greater EMI protection and enhances signal integrity, thereby increasing the materials and labor associated with the manufacture of these cables.

The selection of connectors is another significant factor in determining the cost of custom cables. Using off-the-shelf plastic connectors is often more economical. The use of industrial, medical, and military connectors generally requires higher tolerances, specialized plating, and compliance testing, which significantly increases the individual pricing of these connectors.

2. Design Complexity: The Hidden Cost Driver

Cable assembly construction complexity contributes to significant pricing variances for assemblies that may look the same.

For example, as you add conductors to a cable assembly, you add additional steps when cutting, stripping, terminating, inspecting, and testing. Therefore, you may find a very expensive high-circuit harness and a very inexpensive low-circuit cable assembly that look practically identical on the outside.

Point-to-point cables with minimal channels are relatively inexpensive. Multiple-channel assemblies with branch points, splitters, or leg points will require more physical work for wire routing on harness boards, which increases labor and inspection time.

Tolerances can significantly affect a pproduct’sfinal price. In general, standard tolerances are cost-effective and straightforward to manufacture. However, if you require high-tolerance specifications, you must invest in more precise fixtures, slower manufacturing processes, and greater quality-control checks, which increase costs and the potential for scrapping.

Lastly, high-speed data cable designs, power and mixed-signal cables, sealed assemblies, and overmolded strain reliefs all increase engineering development time and verification and process-control costs.

3. Manufacturing Process and Labor

The construction of a cable plays a significant role in determining its final price.

Labor savings and increased repeatability are achieved through automation in cable cutting, stripping, and crimping. On the other hand, most custom cable manufacturing processes rely on skilled human labor to perform all the complex operations required to assemble a cable, including soldering, ultrasonic welding, routing around obstacles and through holes, and overmolding connectors.

Every time an additional operation is performed during the cable assembly, more labor, documentation, testing, and traceability are required. Custom fixture designs, harness boards, and tools also significantly increase the pproject’soverall costs, especially in the initial phases of production.

4. The NRE Factor: Non-Recurring Engineering Costs

Most custom cable projects involve one-time setup costs known as NRE (Non-Recurring Engineering).

NRE typically covers:

- Custom molds for overmolding or sealed structures

- Dedicated crimp tooling or applicators

- Assembly fixtures and harness boards

- Test fixture development and programming

- Engineering drawings and controlled documentation

Although NRE increases initial investment, it enables stable manufacturing, repeatability, and long-term quality control.

5. Testing, Quality Control, and Compliance

The purpose of testing is to achieve cost savings and protect against non-compliance.

Basic continuity testing confirms that electrical connections are correctly established. Custom professional cables generally require additional testing, including high-potential (hi-pot) testing, impedance measurements, signal-integrity testing, mechanical stress testing, and environmental aging testing.

To comply with applicable standards (IPC/WHMA-A-620, UL, ISO, IATF), documentation of processes, trained inspectors, traceability, and controlled production environmentsare in place for each Cable Manufacturer. These additional costs associated with these systems significantly reduce the probability that a customer will have to rework or return an item, thereby offering significant savings for the manufacturer.

6. Order Volume, Lead Time, and Logistics

Production volume significantly impacts unit price.

Prototype and low-volume orders have a higher unit cost because engineering, setup, tooling, and testing are spread across fewer assemblies. Once volume increases, fixed costs are absorbed within the entire volume produced, and automation can be utilized to reduce per-unit costs.

Lead time also affects costs. Expedited production typically requires overtime labor, priority sourcing of materials, and reallocation of production capacity: packaging and labeling standards, as well as the shipping method, further influence delivered pricing.

7. Hidden Costs Buyers Often Overlook

A low quoted price does not always mean that the total cost is the lowest.

Poor design, poor crimp quality, unrecorded design changes, and inadequate testing often lead to production delays, warranty claims, and field failures. These costs usually exceed the price of the original product many times over.

When evaluating actual costs, it is essential to include your ssuppliers’engineering support, process controls, documentation discipline, and quality systems.

8. How to Reduce Custom Cable Assembly Costs

Good cost management begins with designing.

Early involvement of DFM enables designers to minimize system complexity, maximize material use, standardize components, and create designs that are amenable to automation. Allowing substitutable and acceptable versions of parts on the BOM, standardising wiring colours and gauges, and planning realistic production levels will improve long-term price stability for components.

The best and most sustainable reductions in cost occur through collaboration with engineering—not through negotiation of pricing at post-quote stages.

9. Why RRomtronic’sApproach Helps Control Cost

Romtronic implements cost-control measures before manufacturing.

Our engineering teams support early design review, manufacturability analysis, and material optimization. By combining automated processing with flexible semi-automatic and manual assembly systems, we efficiently support both high-mix low-volume programs and scaled production.

In-house testing, strict Quality Control systems, and structured Process Management reduce rework, improve output stability, and maintain product consistency over the long term, all of which contribute to visible and hidden cost controls.

Conclusion

The price of a custom cable assembly is affected by several factors, including the design, production (including manufacturing discipline), quality assurance, and risk management.

Understanding these factors will allow you to create better designs, budget more accurately, and produce more reliable producrighte “”ight””supplier will do more than offer the lowest price; they will be able to reduce the total cost of the product from beginning to end.

Before beginning your custom cable and wire harness project, the best way to initiate the process is to have a technical discussion about your application needs and specifications.

Frequently Asked Questions

Material selection, design complexity, manufacturing processes, testing requirements, and production volume are the primary cost drivers. Labor and engineering input often influence cost as much as raw materials.

Because setup, engineering, tooling, and testing costs are spread across fewer units. As production volume increases, these fixed costs are absorbed, significantly reducing the per-unit price.

Drawings or schematics, cable length, wire gauge, connector part numbers, performance requirements, compliance standards, target quantities, and delivery timelines.

NRE (Non-Recurring Engineering) refers to one-time setup costs for tooling, molds, fixtures, test development, and engineering documentation required to support stable production.

Early DFM involvement, simplified structures, standardized components, and automated design reduce labor, scrap, and long-term manufacturing risk.

Custom Cable Assembly RFQ Checklist

Providing the information below allows manufacturers to deliver faster, more accurate quotes and avoid unexpected cost increases later.

Design Information

- Cable drawing or schematic

- Cable length and tolerances

- Circuit count and pinout

- Branching or harness layout

Electrical Requirements

- Voltage and current

- Signal type or data rate

- Shielding and EMI needs

- Impedance or loss targets

Mechanical & Environmental

- Operating temperature range

- Flexing or motion requirements

- Chemical or moisture exposure

- Sealing or strain-relief needs

Production Requirements

- Prototype and production quantities

- Target cost expectations

- Compliance standards (IPC, UL, ISO, IATF, medical, etc.)

- Packaging and labeling requirements

- Target delivery schedule

Ready to get an accurate cost for your custom cable assembly?

Romtronic does not give vague estimates; instead, we have an engineering team that takes your drawings, specifications, and application requirements to create pricing that is either clear or optimized, and to identify potential savings even before production begins for new products or when scaling products.

For this reason, contact our team today to obtain an engineering-backed quote as quickly as possible and see what we can do to help you find the right balance of performance, reliability, and cost.

.avif)

Sam Wu is the Marketing Manager at Romtronic, holding a degree in Mechatronics. With 12 years of experience in sales within the electronic wiring harness industry, he manages marketing efforts across Europe. An expert in cable assembly, wiring harnesses, and advanced connectivity solutions, Sam simplifies complex technologies, offering clear, actionable advice to help you confidently navigate your electrical projects.