Selecting the correct USB cable assembly is crucial for any device design. A mismatched cable can cause data loss, power issues, or failure under stress. Key considerations include connector type, USB standard (version), cable length, wire gauge, shielding, and jacket material. Designers must strike a balance between performance (data rate and power) and environmental considerations (EMI, temperature, and flexibility). This guide takes you through each consideration step by step.

Key Factors to Consider:

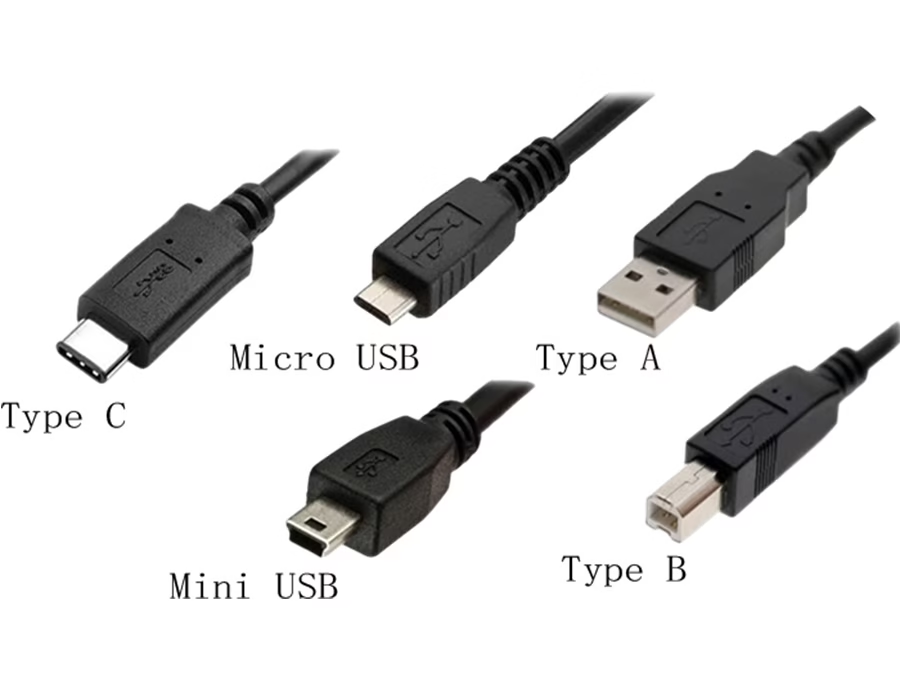

- Connector Type: Match your device’s ports (USB-A, USB-B, USB-C, Micro/Mini). USB-C is reversible and high-speed; USB-A and USB-B are legacy shapes.

- USB Version: Consider the required speed and power: USB 2.0 (480 Mbps), 3.x (5-20 Gbps), and USB4 (up to 40 Gbps). Newer cables can be used with older ports, but at a slower speed.

- Power Requirements: High-current cables (e.g., USB-C PD up to 5A/20V) require bigger conductors. When charging, ensure that the cable supports USB Power Delivery (PD) or Quick Charge.

- Cable Length: Don’t exceed USB requirements (e.g., ~5 m for USB 2.0, ~3 m for USB 3.x, ~0.8 m for USB4). Longer runs increase resistance and delay, reducing signal and voltage.

- Wire Gauge & Construction: Thicker wires (smaller AWG) can carry more current. USB 2.0 cables typically employ 26 AWG power wires, but USB-C harnesses can include 16 to 24 conductors (multiple differential pairs).

- Shielding: Shielding is necessary to protect high-speed data from electromagnetic interference (EMI). SuperSpeed USB cables utilize twisted differential pairs with foil shields, enclosed within an overall braided shield. Shielded designs (foil + braid) ensure signal integrity in noisy environments.

- Jacket Material: Choose based on the environment. PVC is low-cost but stiff and less durable; TPE (or TPEE) is flexible and typically flame-retardant; nylon-braided jackets offer the best abrasion resistance and anti-kink performance.

- Quality & Certification: Use cables with USB-IF or UL certifications. Certified cables fulfill safety/performance standards. Look for renowned brands, USB-IF emblems, and flame-retardant ratings (e.g., UL94 V-0).

- Custom Options: For bespoke assemblies, you can specify the exact length, connector angles, color coding, strain relief, labeling, and other details to suit your specific needs. Many manufacturers (e.g., Celestix, Romtronic) offer custom USB assemblies with molded connectors and testing.

Keeping these points in mind will ensure your USB cable matches both the functional and environmental needs of your project.

Connector Types and USB Versions

Every USB cable must fit the ports at both ends. Standard connectors include USB-A (a regular rectangular host plug), USB-B (a square “printer” form), USB-C (a thin, reversible plug), and older Mini and Micro plugs. For example, a laptop’s USB-C connection requires a C-to-C cable, whereas most chargers use either USB-A or USB-C.

In practice, make sure the plug on your device matches the jack on the cable; a USB-A plug will only fit a USB-A jack. It’s worth noting that modern USB-C can also transport additional modes (such as video) and high power, whereas Lightning (Apple) is proprietary and incompatible with USB standards. Also, check the USB version compatibility. USB3.x and USB4 cables contain more internal wires than USB2.0 cables and handle multi-gigabit transmission via additional SuperSpeed pairs.

A USB 3.0 cable (often with a blue insert) will function in a USB 2.0 port, but only at USB 2.0 speeds. In short, select physically compatible connectors and a cable rated for at least the highest USB version supported by your device or host.

Data Rate, Power Delivery, and Use Case

Consider your project’s data or power needs when selecting a USB cable. For data transfer, choose a cable with a USB standard that meets your speed requirements, such as USB 2.0 at 480 Mbps, USB 3.0/3.1 (Gen 1/Gen 2) at 5-10 Gbps, or USB4 at 20-40 Gbps. For large file transfers or video applications, use a USB 3.0 or higher.

For power delivery, check if your device supports fast charging. USB Power Delivery (PD) cables can carry up to 100 W (20V, 5A) on a USB-C line. High-power cables often use 24 AWG or 22 AWG copper for +5V/+12V lines to minimize voltage drop. If you need Quick Charge (QC) or other protocols, confirm that the cable and connector support them.

Also, keep charging wires as short as possible: long, thin cables might reduce current and charging speed. To summarize, select a cable that is rated for the appropriate USB version and power specification.

Cable Length, Wire Gauge, and Signal Integrity

Length is an important physical constraint. USB standards stipulate maximum passive cable lengths to ensure signal quality: around 5 meters for USB 2.0, 2-3 meters for USB 3.0/3.1, and 0.8 meters for 40 Gbps USB4 cables. Exceeding thresholds can result in packet errors and voltage drops. (For really long distances, active repeaters or hubs may be necessary.)

| USB Standard | Max Data Rate | Max Passive Cable Length |

|---|---|---|

| USB 2.0 | 480 Mbps | ~5 m |

| USB 3.0 / 3.1 Gen1 | 5 Gbps | ~2–3 m |

| USB 3.1 Gen2 / 3.2 Gen2 | 10 Gbps | ~3 m |

| USB4 (40 GB) | 40 Gbps | ~0.8 m |

Furthermore, longer cables increase resistance (see voltage drop) and transmission latency. A 10 m USB 2.0 cable is not recommended due to significant power loss. If your project requires a more extended reach, consider active extension or a repeater hub.

Wire gauge is also essential; narrow wires limit current and have higher resistance. Standard USB power lines are typically 26 AWG; however, thicker wires (24 AWG or lower) can provide superior performance and longer distances. To transport multiple high-speed lanes, USB-C cables with SuperSpeed differential pairs may comprise 16-24 unique conductors in total, which is double the number of wires seen in previous USB-A cables.

In short, keep cords to the specified length for your USB version and select wire thickness based on current/power requirements.

Shielding, Insulation, and Cable Jacket

High data rates and extreme conditions necessitate the use of adequate shielding and protective gear. For USB 2.0 (480 Mbps), a basic foil or braid barrier is generally sufficient. For USB3.x and USB4, the cable geometry is more complicated: SuperSpeed data is sent using differential pairs that are each covered in foil, as well as an overall braided metal shield. This multi-layer shielding keeps electromagnetic interference (EMI) from degrading high-speed transmissions.

In fact, search for cables that include both foil and braided shields, particularly for industrial or high electromagnetic interference (EMI) applications.

Cable jacket materials vary depending on the use case. Standard options include PVC, TPE (thermoplastic elastomer), and nylon braid:

- PVC – Cheap, flame-resistant, yet rather stiff and less durable. PVC jackets have low wear resistance and can become brittle in cold temperatures. PVC is suitable for low-cost consumer cables where flexibility is not required.

- TPE/TPEE – Softer and more flexible (ideal for confined places), and frequently UL94 V-0 rated (flame retardant). TPE is more abrasion-resistant than PVC and free of halogens. It’s a popular option for high-quality cables.

- Nylon Braided – The toughest option. A braided nylon sleeve significantly boosts tensile strength and resists kinks. According to industry data, nylon jackets have “superior wear resistance” even in outdoor, high-intensity use. They also look better and prevent tangling.

Choose the jacket based on your environment: For outdoor use or frequent bending of wires, nylon or high-flex TPE is best. For cables within equipment or dry labs, PVC may be sufficient. In any case, an appropriately rated jacket (often UL/CSA certified) enhances durability and safety.

Build Quality, Strain Relief, and Certification

Beyond electrical specifications, consider mechanical quality. Overmolded or strengthened connectors give strain relief, preventing the cable from breaking at the plug. Braided or thick rubber sheaths are resistant to abrasion. Check the connector plating and build. Gold-plated pins withstand corrosion after thousands of plug cycles.

Certification is also essential. Cables from reputable manufacturers often have USB-IF certification, UL recognition, CE/ROHS markings, and other certifications. These confirm that the cable has passed safety and compatibility tests. For example, Apple products require MFi-certified cords. High-wattage USB-C cables may be marked with the 240W EPR rating. Avoid using unmarked, inexpensive cables; counterfeit or poorly constructed cables might overheat or harm electronics. In brief, purchase certified cables or have them custom assembled from reputable sources.

Finally, evaluate any applicable regulatory or environmental obligations. Industrial or medical devices may require a UL94 V-0 flame rating or particular halogen-free materials. If your project needs such specifications, ensure that the cable fits them (many bespoke cable houses provide UL94 ratings and material certificates).

Customization and Assembly Tips

One benefit of custom cable construction is the ability to provide complete customization. You can customize not only the length and connectors, but also color coding, text printing, and packaging. OEM designers, for example, often incorporate logo printing or colored jackets into their brand designs. Custom assembly may include power-only versions (without data cables) or multi-headed hubs.

Early communication with the provider is essential. Please provide the specific connection models, pinouts, length, and bend radius, shielding requirements, and any environmental variables. Manufacturers utilize “house tools” (standard molds) to save money and time when producing common connectors.

If you require a unique overmold form or additional strain relief, it may increase tooling costs but result in higher reliability. They can also do testing (continuity, insulation, and flex endurance) to confirm that your custom cable works as planned. In brief, explicitly define all mechanical and electrical requirements so that the cable is custom-made for your design.

FAQs

A: Yes. USB 3.0 cables are backward compatible with USB 2.0, but they will function at a lesser speed. Using a higher-end cable in an older port will not result in faster performance.

A: It depends on the USB specification. Passive cables are typically limited to ~5 m for USB 2.0, 2-3 m for USB 3. x, and less than 1 m for 40 Gbps USB 4. Longer lengths necessitate active repeaters or hubs to ensure signal integrity.

A: For USB2.0 and lower, a single foil/braid shield is frequently sufficient. However, to eliminate EMI difficulties with multi-gigabit signals from USB 3. x and USB 4, properly shielded pairs and an overall braid are recommended.

A: Match it to the surroundings. PVC is suitable for cost-sensitive, low-flex applications. TPE or flame-retardant elastomers are recommended for flexibility and safety. A nylon-braided jacket is the most durable option for rough or outdoor use.

A: Look for USB-IF, UL, and CE marks on the cable or datasheet. These results demonstrate that the cable meets industry standards. Avoid using uncertified wires, particularly in critical or high-current applications.

By carefully considering the type of connector, USB standard, length, shielding, and quality, you can select or design a USB cable assembly that meets the specific requirements of your project. The perfect cable maintains your signals intact, your power stable, and your device functioning properly in its intended setting.

.avif)

Sam Wu is the Marketing Manager at Romtronic, holding a degree in Mechatronics. With 12 years of experience in sales within the electronic wiring harness industry, he manages marketing efforts across Europe. An expert in cable assembly, wiring harnesses, and advanced connectivity solutions, Sam simplifies complex technologies, offering clear, actionable advice to help you confidently navigate your electrical projects.