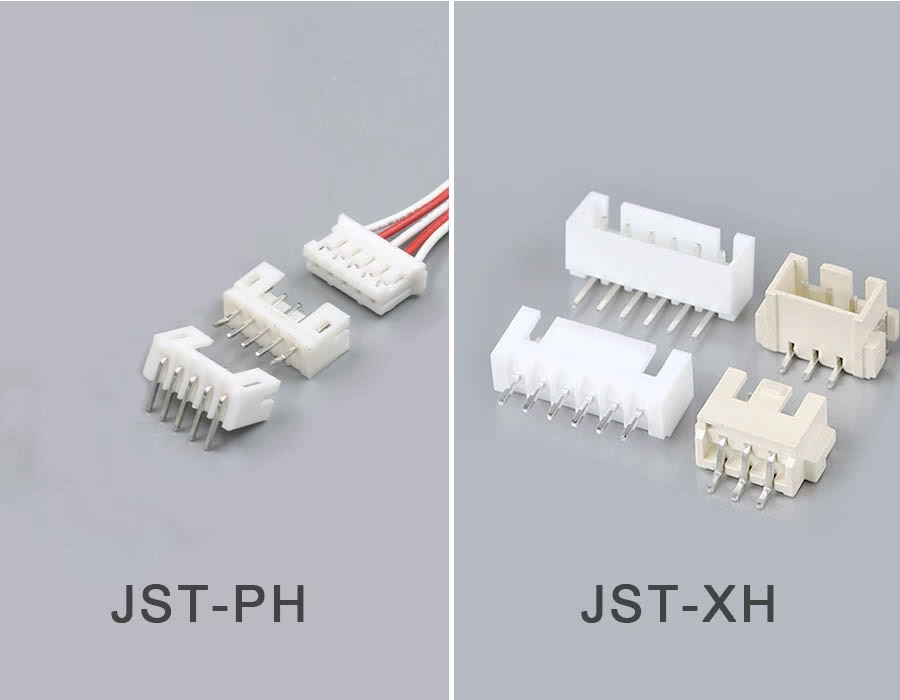

Have you ever been ready to plug a JST connector, only to find that it doesn’t fit? You were probably confusing the JST-XH with the JST-PH. Both connector series are single-row, wire-to-board applications. However, both series are quite different. The JST-XH series features a 2.5 mm pitch (pin spacing) and is designed for high-power applications, whereas the JST-PH series has a 2.0 mm pitch and is intended for more compact and low-power applications.

In practice, the XH series connectors are larger in housing and can therefore handle more current than the PH; in fact, the spec sheet for the XH indicates that it can handle 3 A (250 V), while the PH is rated for 2 A (100 V). The specifications are summarized in the table below:

| Feature | JST-XH | JST-PH |

|---|---|---|

| Pitch (pin spacing) | 2.50 mm (0.098″) | 2.00 mm (0.079″) |

| Max Current (per pin) | ~3 A | ~2 A |

| Voltage Rating | ~250 V | ~100 V |

| Wire Gauge (AWG) | 30–22 | 32–24 |

| Max Pins | 1–20 (single-row) | 2–16 (single-row) |

| Locking Tab | Friction latch (large) | Friction latch (small) |

Put simply, you can think of the JST-XH connector as the “muscle” connector and the JST-PH connector as the “mini” connector. The JST-XH’s spacing is 2.5 mm, which is similar to the old-fashioned style perfboard headers (2.54 mm); the JST-PH connector is noticeably smaller at 2.0 mm.

This means that, functionally, the XH connector can typically carry about 50% more current compared to the PH connector. If you need to deliver current to power boards with LEDs, small motors, or sensor boards, the PH connector may be sufficient to provide power; however, if this is a power delivery to power rails or RC battery leads, the XH connector is the safer option. (I personally learned this lesson when my LED strip connector literally melted under 3 A on the PH plug!)

Another fundamental distinction is a mechanical one. Both series utilize a friction-style latch, but PH without a positive locking tab, as seen on some larger JST varieties. In fact, the PH housings do not even have a dedicated lock – they require a molded friction fit for the plug and header to stay connected. The XH connectors have a latch (the header features a small tab); it’s still a simple friction lock, not a heavy-duty clip, but the thicker XH housing generally feels stronger.

In practice, neither PH nor XH uses a snap-button – take it easy and make sure it’s all the way in. (Pro tip – when the balance plug on your RC battery feels loose, it’s probably only a PH connector going loose. A little tape will help keep it together!).

Regardless of specifications, the application scenario is paramount. Components based on JST-PH connectors are widely used in small consumer circuit boards, lithium polymer battery balance cables, and stepper motor cables. Their miniaturized design allows for accommodating more cables in limited spaces. On the other hand, components based on JST-XH connectors are more commonly found in power supply circuit boards, servo motor cables, or any application requiring higher reliability.

For example, laptop battery packs use JST-XH or similar 2.5 mm plugs to supply main power, and the balancing leads (the small test wires) use JST-PH. In factory automation or 3D printers, thermistor wires or endstop sensors may use PH, and motors or heated beds may use XH.

It is easy to mix them up while on the bench, but it can get expensive. Fortunately, you cannot seat a PH plug on an XH header (the 2.0 mm plug is too narrow), and vice versa; the XH plug will not fit into a 2.0 mm hole. Please don’t force it! Always align pitch. The male headers may appear the same to the untrained eye, but remember: 2.5 mm = XH, 2.0 mm = PH. I keep a quick caliper check in my toolbox for this reason.

FAQs

A: JST-XH has a 2.50 mm pin pitch and is rated for up to ~3 A (AWG #22) and 250 V. JST-PH has a 2.00 mm pitch and is rated for ~2 A (AWG #24) and 100 V.

A: No. Pitch is different; a 2.0 mm PH plug will not make a proper connection to a 2.5 mm XH header, and vice versa. Always use a matching series.

A: Both connectors use a simple friction latch. JST-PH connectors do not have a positive locking tab in the housing; they hold together due to tight tolerances. JST-XH connectors do have a basic friction-lock tab (for lack of better description) to make the mating connection feel more positive. In summary, both use a friction latch; neither has a snap-on lock. JST-PH is slightly less secure under vibration.

A: JST-XH is for about 30-22 AWG wire; it is rated for higher current. JST-PH is designed for finer wires, usually 32-24 AWG.

A: JST-PH (2.0 mm) is common in compact electronics: LiPo balance leads, cameras, small sensors, or stepper motor connectors. JST-XH (2.5 mm) is used in heavier-duty applications, including power connectors on PCBs, servo/motor leads, and larger battery packs. Choose PH for tight spaces or low current, and XH for bulkier, high-current applications.

For guidance on choosing the correct connector for your PCB or harness, check out: How to Pick the Right JST Connector for PCB Harness.

Summarize

JST-XH and JST-PH may appear similar at first glance, but their pitch, current rating, and latch style cater to distinct niches. Double-check those specs – it can save your project! By matching the correct series (and observing the 2.5 mm vs 2.0 mm rule), you ensure reliable, safe connections every time.

Other related content:

For custom JST cable assemblies tailored to your project, see: Custom JST Cable Assemblies.

For a more detailed breakdown of JST connector types, check out: Comprehensive Analysis of JST Connector Types.

.avif)

Alex Wang is the Marketing Manager at Romtronic, with a degree in International Business and over seven years of experience in the electronic cable and wire harness industry. He leads marketing efforts across North and South America, combining deep industry knowledge with strong sales experience.

In addition to overseeing global marketing strategy, Alex is also responsible for content development and editorial coordination, ensuring that Romtronic’s messaging remains clear, consistent, and engaging. His strength in market analysis and customer-focused approach helps clients make more informed purchasing and sales decisions.