M8 connectors are compact, circular connectors widely used to link sensors and actuators in robotic systems. The “8” refers to the 8 mm threaded metal shell. Despite their small size, high-quality M8 connectors often feature brass or stainless shells with sealed O-rings, providing IP67/IP68 protection to keep dust and water out, even in harsh factory conditions. This rugged design means an M8 connector can reliably carry low-voltage power or signals (typically around 0.5–4 A per pin) in demanding environments.

What is an M8 Connector?

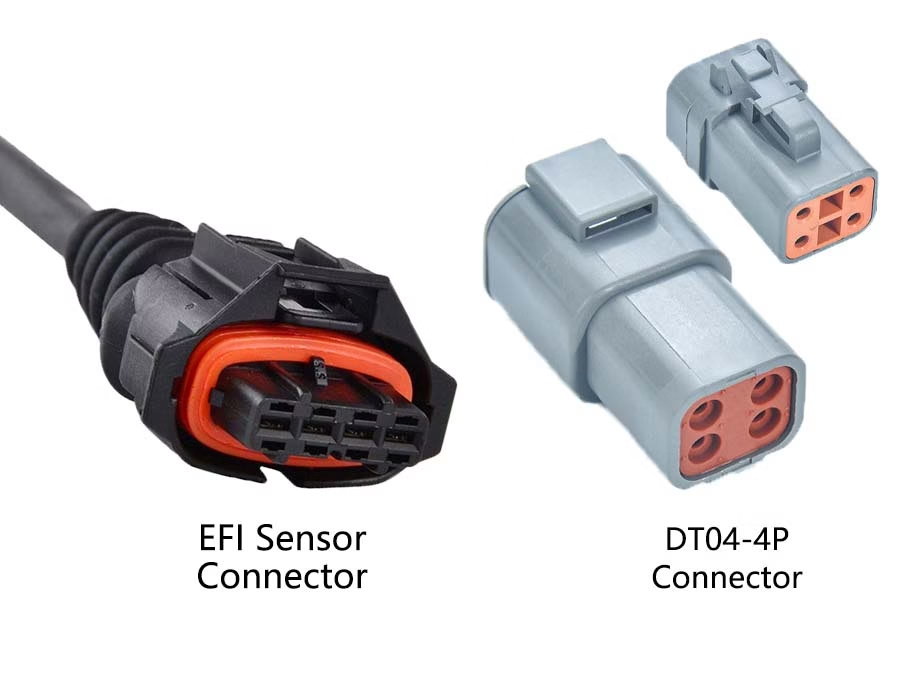

M8 connectors follow IEC standards for metric circular plugs. They typically come in 3-, 4-, or 5-pin versions (some A-coded types even have up to 8 pins). The most common style is A‑coded (3–5 pins) for general sensors, while a B‑coded version (5 pins) is used for special signals or high-speed interfaces. Each pin typically carries a current of 0.5–4 A at low voltages (approximately 50–60 V DC). Because they’re standardized, M8 connectors are available in many configurations – straight or right-angle, cable-mount or panel-mount, push-pull snap-lock variants, etc. This versatility lets designers plug them into a wide range of equipment with minimal fuss. Mechanical keying (via the A/B codes) ensures that you can’t accidentally mate an incompatible connector, thereby preventing wiring mistakes.

Space-Saving, Rugged Design

M8 connectors excel in tight spaces. Their 8 mm thread is much smaller than, say, an M12 connector, allowing placement on cramped robot arms and sensor housings. Yet they remain fully industrial-grade: the metal housing and seals provide IP67/IP68 ratings, ensuring M8s are both dustproof and waterproof. They’re built to withstand shock and heavy vibration – an all‑metal shell won’t break under a bump on the factory floor. In summary:

- Compact size: Fits in confined spaces on robotic end-effectors and cables.

- Rugged build: Brass/Stainless shell resists impacts and vibration.

- Waterproof sealing: IP67/68 seals protect electronics against dust, splashes, or washdowns.

The small, sealed connectors stay reliable even in a busy factory environment. Robots often have many moving cables. The small form factor of M8 connectors lets engineers route wiring on moving joints without interference. And because they lock by screw thread (or snap), vibration won’t loosen the connection during operation. Even if a robot is sprayed with coolant or oil, an IP‑sealed M8 connector keeps the electronics safe.

Easy Plug-and-Play Installation

One of the most significant benefits is the speed of installation. Most M8 connectors come pre-molded on short cables. That means instead of hard-wiring each sensor, you match the keyed plug and twist it on – no soldering or terminal blocks needed. This plug-and-play setup reduces labor: technicians can plug sensors directly into controllers without needing an electrician. Fewer wires to tie and screw also means fewer errors. Standard keying and coding on M8s further prevent mis-wiring. For example, an A-coded 3-pin cable physically won’t fit into a B-coded 5-pin socket, thereby avoiding incompatible connections.

| Feature | M8 Connector | M12 Connector |

|---|---|---|

| Thread Diameter | 8 mm | 12 mm |

| Typical Pins | 3–5 (up to 8) | 3–12 (up to 17) |

| Current per Pin | ~3 A | ~4–5 A (up to 10 A) |

| IP Protection | IP67/IP68 | IP67/IP68 (some IP69K) |

| Common Use | Tight sensors/actuators | General sensors, Ethernet, I/O |

Table: Quick comparison of M8 vs M12 connectors. M8 offers a smaller footprint while providing similar robustness.

Standardization & Versatility

Because M8 connectors meet global standards, they’re interchangeable across brands (as long as coding and pin count match). Engineers appreciate this consistency. For example, you can use any A‑coded M8 cable on any A‑coded sensor port, even from different manufacturers. Other useful points:

- Coding keys: A- and B-codes prevent the wrong cable from being plugged into a device, protecting equipment.

- Configurations: M8s come in many styles – straight or right-angle cables, panel-mounted receptacles, even push-pull snap connectors. This lets designers fit them neatly into almost any layout.

- Guided variants: Some M8 connectors add alignment keys (guided M8). These are great for “blind” connections or tight spots: the keys ensure the plug snaps in only the correct way, avoiding bent pins. Push-to-connect versions of guided M8 also exist for tool-less, quick mating (handy when assembly is tricky).

Applications in Robotics

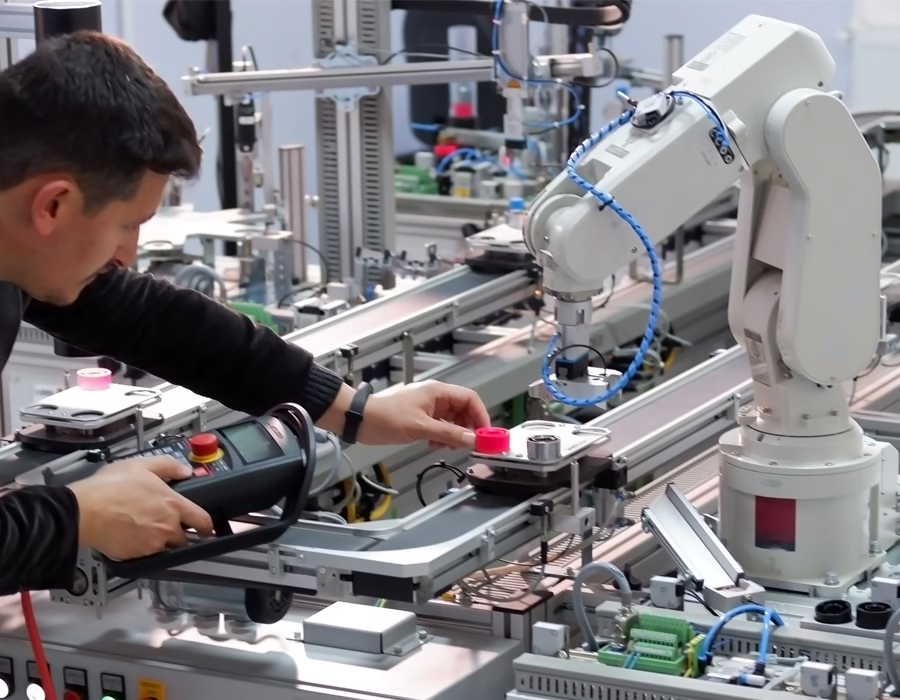

In robotics, M8 connectors are everywhere. They include power and signal limit switches, sensors, encoders, gripper tools, and more. Many robot arms and end-effectors are designed with M8 sensor ports on the tool flange. Using M8s reduces clutter: for instance, a network of safety light barriers or proximity sensors can each utilize a single M8 cable to connect back to a controller. Because these connectors are sealed and rugged, they’re trusted in conveyor systems, machine vision setups, or any area where cables might flex.

In setups like this, M8 connectors reliably link sensors and control boxes. In practice, M8 connectors save real time. If a sensor needs replacement, a technician unplugs the M8 cable and snaps in a new one – no re-crimping or wiring required. This modularity reduces downtime. On a busy factory line, using plug‑in M8 sensor cables instead of hard-wiring can halve installation and maintenance effort.

FAQs

A: M12 connectors are larger (12 mm thread) and can handle more current or more pins (up to 17). Use M8 when space is tight and you only need a few amps of low-voltage signal. Use M12 for higher power, Ethernet, or applications that require multiple pins. Both are rugged, but the M8 wins in compactness.

A: “M” denotes metric screw thread size. An M8 connector has an 8 mm central diameter thread. (By contrast, an M12 has a 12 mm thread.)

A: Commonly 3 or 4 pins, with 5-pin also popular. Some specialized M8s even go up to 6 or 8 pins. The pin count is chosen to match the device (e.g., 3 pins for simple switches, 4 pins for analog sensors).

A: Yes. Standard M8 connectors are sealed to IP67, meaning they are dust-tight and protected against temporary immersion in water. Many are rated IP68 (for continuous submersion) or even IP69K (for high-pressure wash-down).

A: These are mechanical keys that ensure only matching connectors mate. A-coded M8 (3–5 pins) is the norm for sensors and DC signals. B-coded (5 pins) is often used for 10/100 Ethernet or high-speed analog signals. An A-coded plug won’t fit a B-coded jack, avoiding wiring mistakes.

A: You could, but using M8 cables is much easier. Pre-wired M8 cables plug in instantly, saving time on wiring. Installers often find they can complete sensor hookups in half the time because there’s no crimping or terminal work – plug and lock. It also makes swaps quick: technicians replace modules by unplugging the M8 instead of cutting and rejoining wires.

.avif)

Sam Wu is the Marketing Manager at Romtronic, holding a degree in Mechatronics. With 12 years of experience in sales within the electronic wiring harness industry, he manages marketing efforts across Europe. An expert in cable assembly, wiring harnesses, and advanced connectivity solutions, Sam simplifies complex technologies, offering clear, actionable advice to help you confidently navigate your electrical projects.