Pull-force testing (a crimp pull test) is a destructive test for crimped wire connections. It measures the tensile force to separate a crimped terminal from its conductor. In the test, one end of the wire is secured, and a constant axial pull is applied.

The force increases until the terminal pulls off or the wire breaks, and the peak force at failure is recorded to indicate crimp quality. Pull testing also ensures good electrical contact (metal-to-metal) at the terminal, preventing poor connections. A repeatable pull test also helps calibrate the crimping equipment.

Working Principles of Pull-Force Testing

Handheld or bench-mounted force gauges can be used to perform pull tests. A handheld gauge measures the tension directly as force is applied (in tension or compression), and these portable gauges can be mounted to a small test stand if needed. For higher consistency, motorized test stands automate the pull speed and data capture.

Specialized grips securely hold the crimped terminal and wire in a pull-force tester. For example, a cable-cam grip self-tightens under load to spread the force and prevent slippage. The tester’s crosshead pulls constantly (often at a rate of ~25 mm/min, as per the standard) until failure. Modern testers display the peak pull force, which reflects the joint’s strength. Because the test pulls until failure, it reveals whether the crimp holds or the wire breaks.

Types of Pull-Force Testers

Dedicated benchtop pull testers are available in both manual and motorized versions. Manual testers (lever- or crank-operated) are portable and straightforward, making them ideal for quick spot checks. Motorized tensile testers use servo or pneumatic drives and a digital controller to maintain a precise pull speed, eliminating human variability. Digital force gauges (often mounted on a test stand) are cost-effective for measuring pull forces in smaller applications.

For high-volume production, fully automated systems with PC-controlled data logging allow rapid testing of large batches.

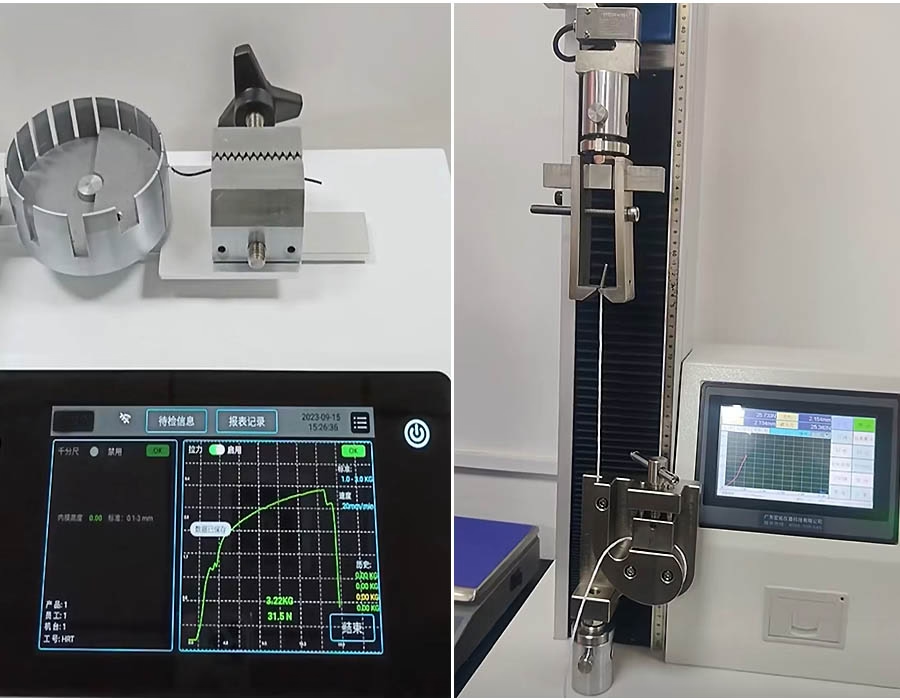

Types of tension testers range from handheld gauges to heavy-duty motorized test frames. The picture above shows two examples of digital motorized pull testers equipped with programmable pull controls, integrated handles, and digital readouts. These motorized systems ensure consistent pull speeds and accurate data collection, making them ideal for high-reliability production. Handheld digital gauges typically handle forces up to approximately 1,000 Newtons (200 lbf).

In contrast, fully motorized frames (shown here) can handle thousands of Newtons of force; these systems capture peak pulling forces and can output data to a PC for logging.

| Tester Type | Features and Usage | Typical Capacity |

|---|---|---|

| Handheld Force Gauge | Portable digital or lever gauge; fits in hand or small stand; good for spot checks. | Up to ~1000 N (200 lbf) |

| Manual Bench Tester | Bench-mounted lever/crank; simple and low-cost; limited speed control. | ~500–2000 N (50–200 lbf) |

| Motorized Tester | Motor-driven stand with digital controller; ensures constant pull rate; USB/PC output. | Up to ~10,000 N+ |

| Automated System | PC-controlled system for high-volume production; automated data logging. | Multi-kN or higher |

Industry Standards and Procedures

Many standards guide pull-force testing. North American wire connectors follow UL 486A/B, which specifies minimum pull-off forces by wire size (for example, AWG 22 terminals must withstand ≥8 lbf). The IPC/WHMA-A-620 standard establishes quality classes for assemblies. Consumer electronics and appliances typically meet Class 2 (standard service) requirements, whereas automotive and aerospace applications often require Class 3 (high-reliability) levels. All standards require a controlled pull speed (e.g., ~25 mm/min) to ensure repeatable results. Many aerospace/military specifications explicitly require a pull (tensile strength) test for connector approval.

Relevance in Automotive and Consumer Electronics

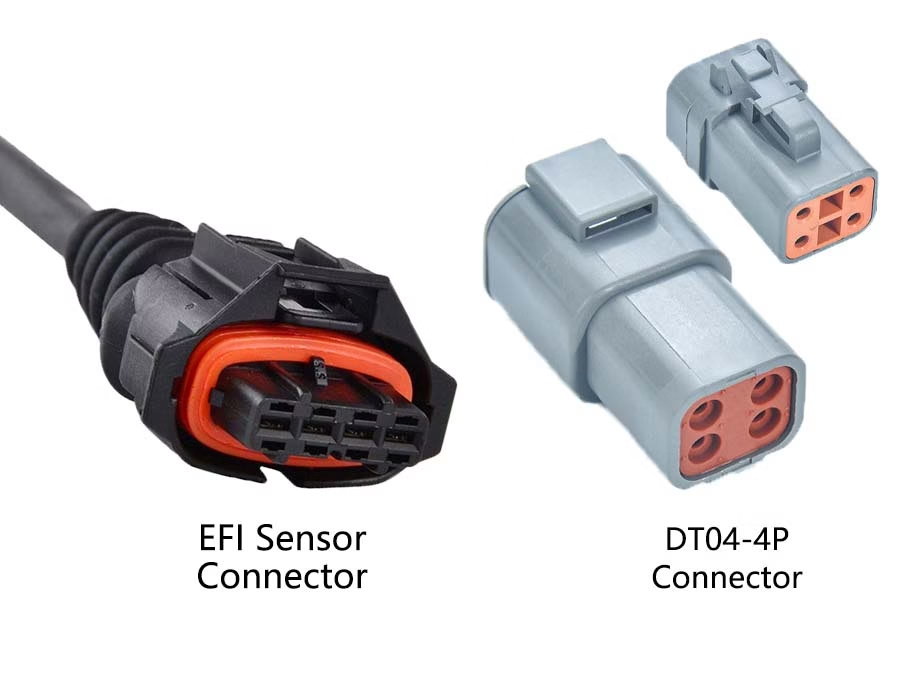

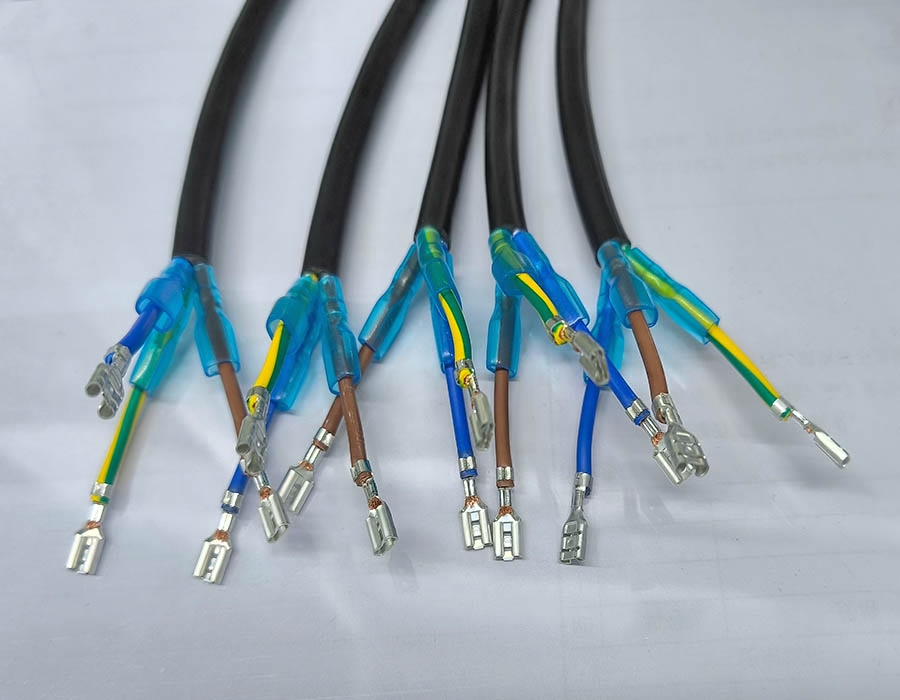

Pull-force (terminal strength) testing is critical in automotive and consumer electronics manufacturing. In automotive terminal testing, each crimp must withstand vibration and thermal extremes. Automotive harnesses carry power and signals in harsh environments, so each crimp must remain securely in place. Many OEMs impose their stringent pull-test criteria on terminals.

In consumer products (TVs, computers, appliances), reliable crimps reduce warranty returns and maintain product reputation. In all cases, pull tests verify good metal-to-metal contact and sufficient mechanical strength, preventing failures.

Common Crimp Testing Issues and Solutions

- Under-crimping/Over-crimping: Too little deformation leaves voids and a weak mechanical grip, while too much deformation can damage the conductor. Both errors yield lower pull strength.

- Improper wire insertion/stripping: The pull force is drastically reduced if the wire isn’t fully seated in the terminal or if strands are cut off during stripping. Always ensure full insertion and a clean strip length.

- Process variability: Worn tooling or inconsistent crimp height leads to wide variations in pull results. Regular calibration and cross-section inspections help maintain consistent crimp quality.

- Testing errors: Slippage, misalignment, or jerky pull motions can skew data. Standards require a constant pull speed, and using self-tightening grips prevents the wire from slipping out during the test.

Romtronic’s Crimp Testing Solutions

At Romtronic, quality starts in our facility. We combine our wire-processing expertise with a fully equipped test lab to deliver reliable crimp pull testing. Our equipment includes calibrated handheld gauges, bench testers, and motorized pull frames, all of which are aligned to industry standards. This means every harness and connector we produce is verified against the required pull-force criteria.

By integrating manufacturing and testing, Romtronic gives engineers and buyers the confidence that their terminals meet or exceed industry requirements for strength and reliability.

.avif)

Sam Wu is the Marketing Manager at Romtronic, holding a degree in Mechatronics. With 12 years of experience in sales within the electronic wiring harness industry, he manages marketing efforts across Europe. An expert in cable assembly, wiring harnesses, and advanced connectivity solutions, Sam simplifies complex technologies, offering clear, actionable advice to help you confidently navigate your electrical projects.