In critical industrial networks, downtime isn’t an option. One broken cable shouldn’t halt production or compromise safety. That’s where redundant ring Ethernet cabling comes in. By creating looped or parallel networks, protocols like MRP, PRP, and HSR ensure continuous communication. But each comes with unique wiring, harness, and hardware requirements. Let’s break it down.

Why Redundant Rings Matter

Redundant rings protect your network from single points of failure. A break in one path automatically reroutes traffic, preventing system interruptions.

- MRP: Single-ring network with predictable switchover.

- PRP: Two completely separate networks for zero-time failover.

- HSR: Single ring where frames travel both directions for seamless recovery.

Tip: Always route redundant cables independently. Two cables in the same conduit can fail together, defeating redundancy.

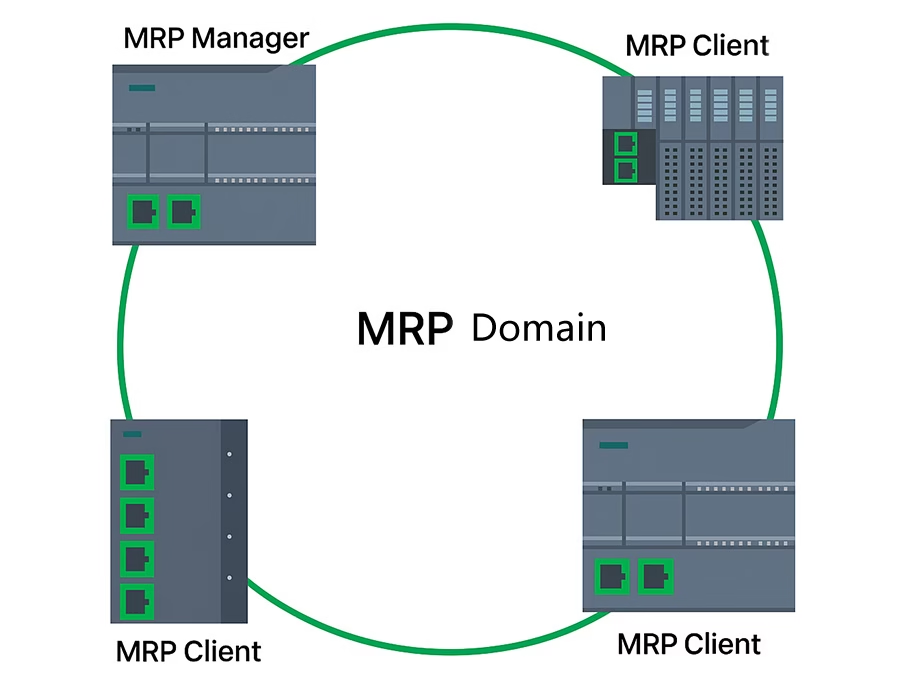

MRP (Media Redundancy Protocol)

Topology: Single ring

Harness Considerations: Requires MRP-capable switches; one acts as Media Redundancy Manager (MRM). The others are clients (MRCs).

Pros: Predictable switchover (~10–60ms), no duplicate traffic, cost-effective.

Cons: Minor switchover delay; single ring limits scalability.

Practical Tip: Ideal for factory floors where cost and ease of setup are more critical than instantaneous failover. Ensure blocked ports and unblocked backup paths are wired correctly to avoid loops.

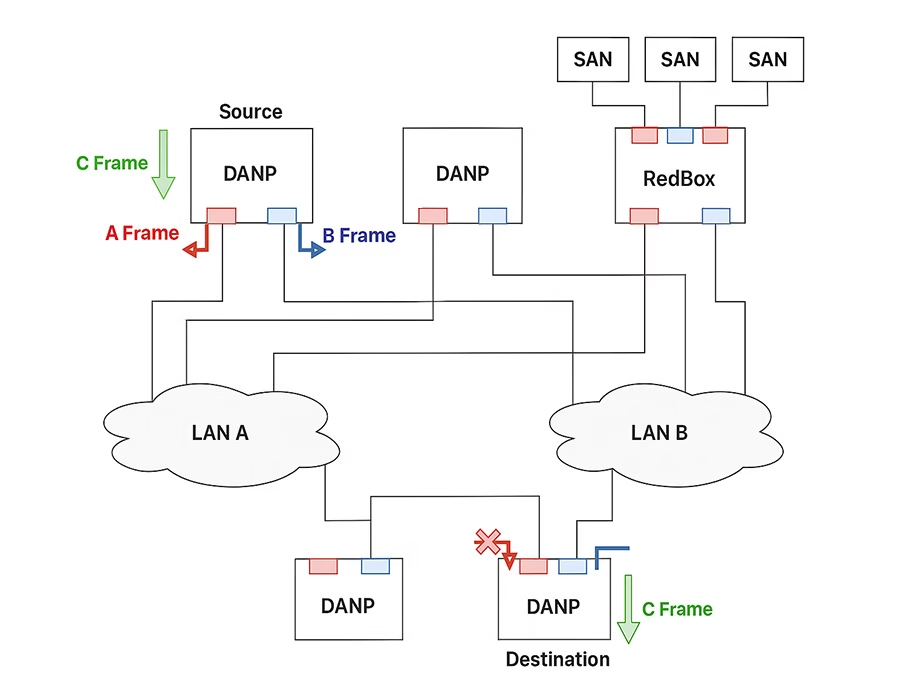

PRP (Parallel Redundancy Protocol)

Topology: Two entirely separate networks

Harness Considerations: End devices must be Double Attached Nodes (DAN P) connected to both networks. RedBoxes allow single-interface devices to connect redundantly.

Pros: Zero-time failover, flexible topology, supports standard devices via RedBoxes.

Cons: Doubles infrastructure costs; requires careful planning for cabling and switches.

Practical Tip: Ideal for high-end substations or any system where downtime is unacceptable. Make sure both networks are physically independent to prevent common-mode failures.

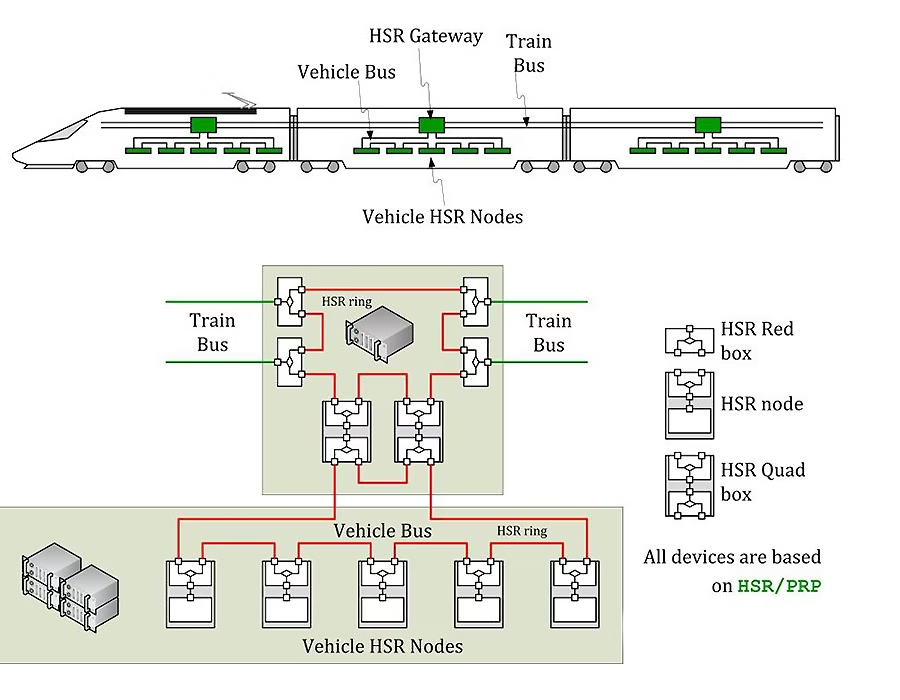

HSR (High-availability Seamless Redundancy)

Topology: Single or coupled rings

Harness Considerations: Devices (DAN H) send duplicate frames in both directions; RedBoxes connect non-HSR devices.

Pros: Zero failover time without a second network; simpler cabling than PRP.

Cons: 50% bandwidth consumed due to duplicate frames; less flexible, mainly limited to ring topologies; practical device limit ~16 nodes.

Practical Tip: Best for ring topologies with moderate device counts. Use RedBoxes or QuadBoxes for SAN devices and larger networks.

General Harness Considerations

- Topology Matching: PRP → double-star networks, HSR/MRP → ring loops.

- Redundant Paths: Physically separate cables to prevent single-point failures.

- End-Device Compatibility: DAN P / DAN H NICs or RedBoxes/QuadBoxes for standard devices.

- Component Verification: Ensure switches, NICs, and coupling boxes support the chosen protocol.

- Application Fit: PRP = max uptime, HSR = seamless failover in a ring, MRP = cost-effective, predictable recovery.

Comparison Table

| Protocol | Topology | Failover Time | Bandwidth Use | Infrastructure | Recommended Use |

|---|---|---|---|---|---|

| MRP | Single ring | 10–60 ms | 100% | One ring, MRP switches | Cost-effective, small/medium factory networks |

| PRP | Two separate networks | 0 ms | 100% per LAN | Full dual network, DAN P or RedBoxes | Critical systems, zero downtime needed |

| HSR | Single or coupled ring | 0 ms | ~50% | Ring of DAN H devices, RedBoxes for SANs | Moderate-scale rings, seamless failover without dual networks |

FAQs

PRP for zero downtime with max flexibility.

HSR for seamless failover in a single ring without a second network.

MRP for predictable, cost-effective recovery with minor switchover delay.

Yes, through RedBoxes (PRP) or RedBoxes/QuadBoxes (HSR), which bridge standard NICs onto redundant networks.

Route redundant cables independently. Avoid shared conduits or bundles for both legs to prevent simultaneous failure.

Generally, no. Each protocol requires specific handling. If needed, use bridging boxes carefully to maintain redundancy integrity.

Summarize

Proper harness design, independent cabling, and the correct protocol choice are critical for resilient industrial Ethernet networks. MRP, PRP, and HSR each have trade-offs—matching them to your application ensures maximum uptime, predictable performance, and robust network integrity.

.avif)

Sam Wu is the Marketing Manager at Romtronic, holding a degree in Mechatronics. With 12 years of experience in sales within the electronic wiring harness industry, he manages marketing efforts across Europe. An expert in cable assembly, wiring harnesses, and advanced connectivity solutions, Sam simplifies complex technologies, offering clear, actionable advice to help you confidently navigate your electrical projects.