IDC (Insulation Displacement Connector) cables are fast, reliable, and cost-effective for connecting wires without stripping the insulation. IDC connectors pierce the wire’s insulation and create a strong connection to the conductor, making them ideal for quick, tool-less assembly. Let’s look at IDC cables, their work, and why they are popular in many industries.

How Does an IDC Connector Work?

IDC connectors are very clever. They use a sharp metal blade to pierce the insulation and contact the conductor rather than stripping it from the wire. This “cold soldering” process creates a strong gas-tight connection without soldering or other tools.

IDC connectors have two main parts:

- Connector Body: This part is usually made of plastic or metal with sharp teeth or blades that cut through the wire’s insulation.

- Pins: This part connects to the individual wires and is usually specially shaped to ensure a strong connection.

Once the connector is pressed into place, the sharp pins pierce the insulation and create a strong electrical connection.

Why Choose IDC Cables?

IDC cables offer some impressive benefits that make them a go-to option for many applications:

- Quick and easy assembly: No wire stripping, soldering or special tools are required. Press the connectors into place, and they will be ready to use. This saves both time and labor costs.

- Cost-Effective: Because IDC cables are quick to assemble and don’t require complicated tools, they are less expensive and a budget-friendly choice for many industries.

- Reliable connection: The piercing action of IDC connectors creates a gas-tight, vibration-resistant connection that ensures the cable remains secure over time.

- Versatile: IDC cables come in various sizes and spacings for projects ranging from small equipment to large systems. They also feature features such as locking clips or strain relief.

Benefits of IDC Cables

| Benefit | Description |

|---|---|

| Fast Assembly | No soldering or wire stripping required. |

| Cost-Effective | Reduces time and labor costs. |

| Reliable Connections | Gas-tight, vibration-resistant connections. |

| Versatile | Available in various sizes and pitches. |

Where Are IDC Cables Used?

Due to their reliable and fast connections, IDC cables are everywhere in electronics. Some typical applications include:

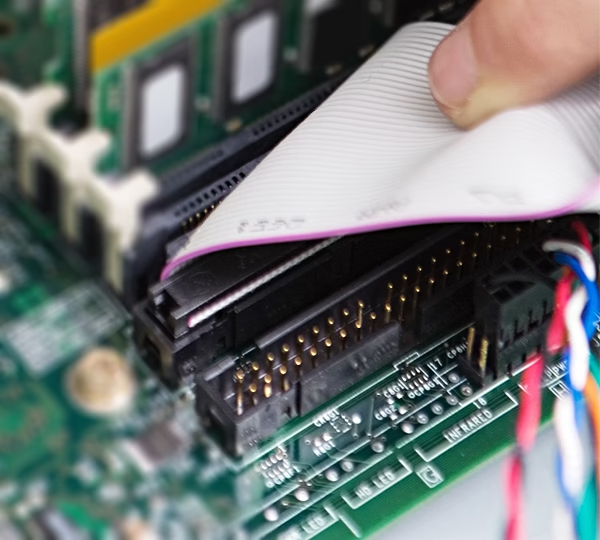

- Computers: Connect devices inside computers, such as hard disks and motherboards.

- Medical: For devices that require precision and reliability.

- Telecommunications: Used in routers, switches and other communications equipment.

- Automotive and Industrial: Essential components such as wiring harnesses and control systems.

Assembling an IDC Cable

Making an IDC cable is simple and requires only a few essential tools. Here is a brief description of how to assemble it:

- Gather the materials: You will need a ribbon cable, two IDC connectors and a press tool.

- Align the connectors: Align the connector pins with the cable ends. Make sure everything is oriented correctly.

- Press the connectors: Press to attach the connectors to the cable, ensuring the blades pierce the insulation and make a firm connection.

The straightforward process requires no specialized knowledge, making it ideal for professionals and DIY projects.

Romtronic: Your Go-To IDC Cable Manufacturer

At Romtronic, we specialize in customizing IDC cable assemblies to meet the specific needs of your project. Whether your project is a telecom, automotive or industrial application, we have the expertise to provide a best-in-class solution. Our team works closely with you to ensure that your IDC cables are of the highest quality, reliable and ready to use.

Conclusion

IDC cables are excellent for fast, reliable, cost-effective wire connections. Their quick assembly, durability, and efficiency make them an excellent choice for various industries, from computers to medical devices. IDC cables are worth considering, whether you are designing a new product or looking for a better solution.

If you are looking for customized IDC cable assemblies, Romtronic is here to help. Contact us today to discuss how our high-quality IDC cable solutions can support your next project!

.avif)

Sam Wu is the Marketing Manager at Romtronic, holding a degree in Mechatronics. With 12 years of experience in sales within the electronic wiring harness industry, he manages marketing efforts across Europe. An expert in cable assembly, wiring harnesses, and advanced connectivity solutions, Sam simplifies complex technologies, offering clear, actionable advice to help you confidently navigate your electrical projects.