The wire harness assembly process helps electronics make wiring easier, i.e., it is a bundle of multiple wires and connectors inside a cover or jacket, which can save space, cost, etc. Such harnesses would improve reliability, reduce installation time, and increase safety, leading to cost benefits. These harnesses can be custom or standard run components, but in every case, the designer allows each harness to do precisely what it needs when efficiently packaged.

Wire Harnesses Designing And Developing

Designing a wire harness begins with understanding the application’s requirements, reviewing your services and schematic layout, and executing facetious statements. Designing tools help in selecting components, and layout planning enables you to ensure that custom drawings are followed accurately.

The Main Steps to Manufacture a Wire Harness

1. Cutting and Stripping Wires

Wires are cut to length, and insulation is stripped using automated machinery to ensure they are adequately prepared for assembly.

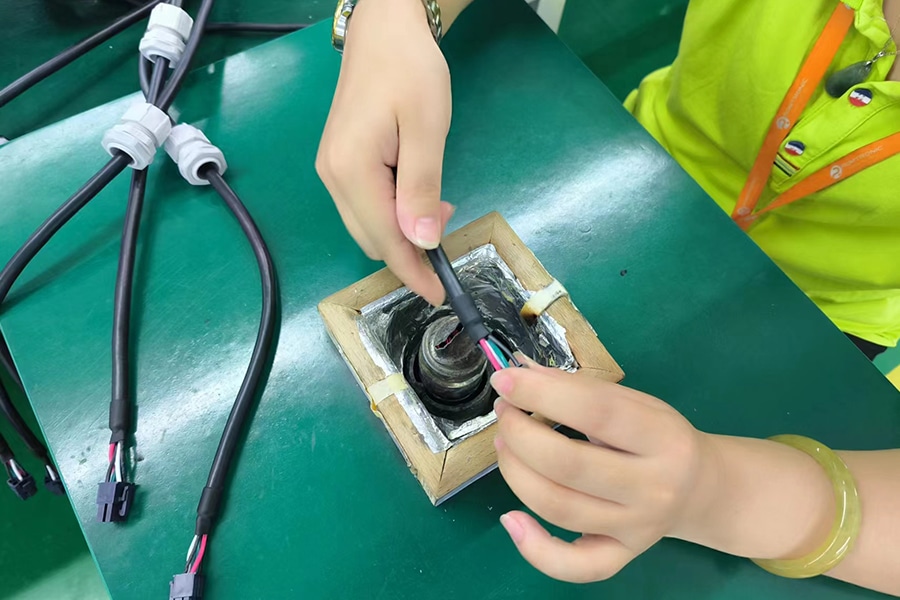

2. Crimping or Soldering

By crimping or soldering, workers attach terminals of connectors onto stripped wire ends for a reliable electrical connection.

3. Terminal Assembly

Crimped terminals are inserted into housings/connectors and mechanically retained to secure an electrical connection.

4. Route and Bundle the Harness

Operators route wires based on design requirements, tying cables together with cable ties and using tape or sleeving as needed to create large bundles of wire that can be neatly crimped.

5. Testing and Inspection

Our hardware tests the wire with specialized equipment to verify both continuity and functionality, and we also physically inspect it for proper routing and damage.

6. Applying Protective Covering

Workers secure the wires with braided sleeves or heat-shrink tubing to protect them from mechanical stress and environmental influences, ensuring long-term reliability and durability.

7. Labeling and Marking

This identification helps maintenance, installation, and troubleshooting workers work faster as wires and connectors are correctly labelled.

8. Quality Approval and Packing Of Product

After a comprehensive final inspection to ensure the highest safety and performance specifications, they are hand-wrapped and ready for delivery.

Components and Materials Used

Wire harnesses contain many components, such as copper or aluminum wires, connectors, terminals, and protective covering materials like PVC or polyethylene. They are designed according to specific application requirements and made from materials that ensure a long service life and the best performance.

Why You Should Use Off-the-Shelf Wire Harnesses

This is especially true compared to custom and tooled solutions—pre-made harnesses are cost-effective and have a nearly immediate lead time after the request for quote lifecycle stages. Mass production provides consistency and adheres to industry specs to be effective in various applications.

Wire Harness Manufacturing Automated

Automation technologies have been known to significantly improve the efficiency of manufacturing processes that require precise wire cutting, stripping, and assembly. Wire harness manufacturing is supported by Robotics and Data analytics, which enhances overall wire productivity and allows quality-controlled workflow. There are fewer chances for errors.

Conclusion

Nowadays, wire harnesses are imperative to modern-day electronic systems that offer effective wiring quality solutions in every sector. From the creation of a preliminary design to validation testing, knowing in great detail what goes on during each step helps maintain harness reliability and performance. This will further increase the speed and precision of wire harness manufacturing, thanks to ongoing advances in automation.

For customized, high-quality wire harnesses, contact Romtronic for one-stop service and reliable products that meet safety standards.

.avif)

Sam Wu is the Marketing Manager at Romtronic, holding a degree in Mechatronics. With 12 years of experience in sales within the electronic wiring harness industry, he manages marketing efforts across Europe. An expert in cable assembly, wiring harnesses, and advanced connectivity solutions, Sam simplifies complex technologies, offering clear, actionable advice to help you confidently navigate your electrical projects.