For Original Equipment Manufacturers (OEMs), submitting a Production Part Approval Process (PPAP) is more than just a means of monitoring suppliers. It is a systematic way to verify that the supplier can provide consistent product quality over time and under normal production conditions, rather than just delivering a product that passes an initial inspection.

Whether for automotive, industrial equipment, agricultural machinery, or energy systems, PPAP has become a standard requirement for mission-critical cable assemblies.

The focus of OEM buyers when evaluating submitted cable assembly PPAP documentation, beyond the paperwork, is detailed in this article, along with common reasons they fail to approve a supplier’s submission.

Why PPAP Is Critical for Cable Assemblies

Cable assemblies may look simple, but from an OEM perspective, they carry hidden risks:

- Crimp quality variations that affect electrical reliability

- Inconsistent stripping or soldering processes

- Measurement errors in pull force or resistance testing

- Material traceability gaps across suppliers

PPAP was developed to confirm that risks associated with the mass production of an assembly are mitigated before mass production begins. An OEM Buyer is approving the manufacturing process and the purchased part.

When a supplier provides custom cable assemblies or manufactures wire harnesses, PPAP can serve as the basis for the supplier’s long-term sourcing decisions rather than being treated as a project-based requirement.

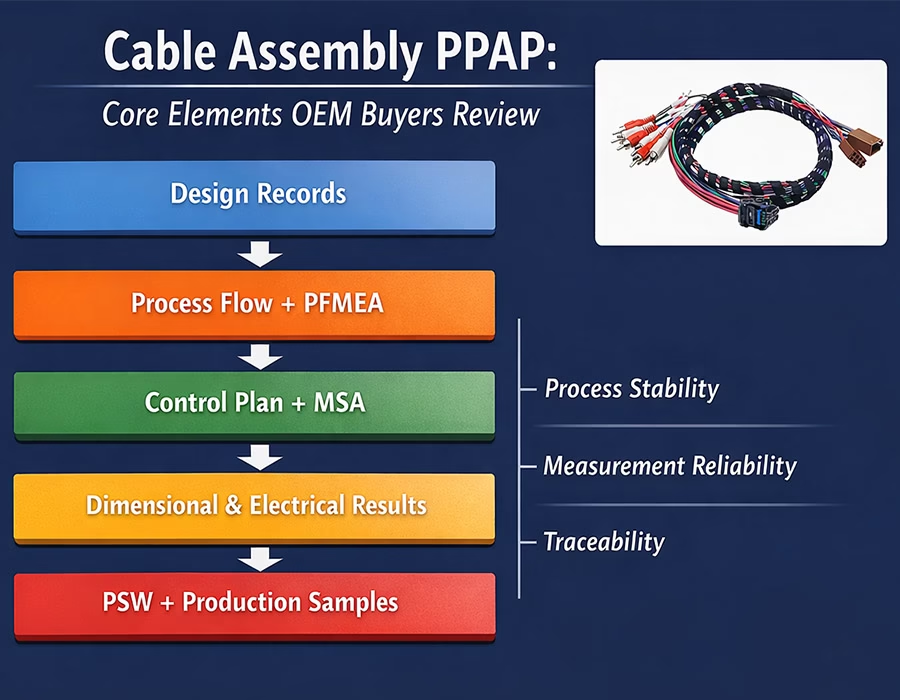

The PPAP Focus Areas OEM Buyers Care About

Although PPAP includes many documents, OEM buyers tend to evaluate submissions through three core questions:

- Is the process stable and repeatable?

- Are measurements reliable and trustworthy?

- Can quality be maintained at production volume?

Anything that does not help answer these questions is usually skimmed. Anything that directly supports them is examined in detail.

Core PPAP Elements OEMs Scrutinize

Part Submission Warrant (PSW)

The PSW is more than a summary form. OEM buyers use it as a declaration of accountability.

Any mismatch between the PSW and supporting documents immediately raises concerns about internal control.

Design Records

OEMs verify that drawings, specifications, and revision levels exactly match the approved versions.

Even minor discrepancies—connector orientation, wire gauge notation, or tolerance format—can delay approval.

Process Flow Diagram and PFMEA

These two documents are reviewed together.

OEM buyers want to see:

- Logical, step-by-step production flow

- Realistic failure modes (not generic templates)

- Clear linkage between PFMEA risks and control actions

For cable assemblies, special attention is paid to crimping, soldering, overmolding, and final inspection.

Control Plan

A strong control plan shows how risks are actually controlled on the shop floor.

OEM buyers look for:

- Critical characteristics are clearly marked

- Inspection frequency aligned with risk level

- Clear reaction plans when results fall out of spec

A control plan that mirrors the PFMEA without operational detail is a common red flag.

Measurement System Analysis (MSA)

MSA is often underestimated in cable assembly PPAPs.

OEM buyers check whether:

- Pull force tests are repeatable

- Resistance measurements are consistent across operators

- Measurement tools are appropriate for small tolerances

Poor MSA results can invalidate otherwise good dimensional data.

Dimensional and Performance Test Results

Beyond basic dimensions, OEMs often focus on:

- Electrical continuity and resistance

- Pull force and retention strength

- Environmental or durability tests (if required)

Consistency across multiple samples matters more than a single “perfect” result.

Material and Compliance Documentation

Traceability is critical.

OEM buyers verify:

- Wire, terminal, and connector material sources

- Compliance with required standards (RoHS, REACH, etc.)

- Lot-level traceability for production samples

This is especially important for wire harness assemblies used in regulated or harsh environments.

Sample Production Parts and Master Samples

Physical samples often influence approval more than documents.

OEM buyers examine:

- Crimp appearance and uniformity

- Strain relief and overmolding consistency

- Overall workmanship compared to drawings

Master samples become the long-term visual reference, so workmanship matters.

Common PPAP Submission Levels for Cable Assemblies

Most OEMs request PPAP Level 3 for cable assemblies. This level provides enough documentation and sample evidence to validate both the product and the production process.

Higher levels may be required for:

- Safety-critical applications

- New manufacturing processes

- High-volume or high-risk programs

What OEM Buyers Evaluate Beyond the Documents

Even with a complete PPAP package, OEM buyers often assess factors that are not explicitly listed:

- Supplier responsiveness during PPAP clarification

- Ability to explain process risks clearly

- Consistency between documents and factory reality

This is where experienced cable assembly manufacturers differentiate themselves—not by perfect paperwork, but by process transparency and technical confidence.

Why PPAP Matters in Harsh Operating Environments

In applications exposed to vibration, temperature cycling, moisture, or chemical exposure, cable assemblies are often failure points.

OEM buyers rely on PPAP to confirm that:

- Crimp and termination processes are robust

- Materials are suitable for long-term use

- Quality controls can prevent gradual degradation

In these environments, PPAP is viewed as a risk-reduction tool, not a compliance checkbox.

Conclusion

For Original Equipment Manufacturers (OEMs), the purpose of the Production Part Approval Process (PPAP) for cable assemblies is to provide assurance and confidence in the stability of the manufacturing process, the repeatability and accuracy of measurements, and the expected quality over time.

Suppliers who view PPAP solely as a means to obtain good paperwork will have difficulty securing product approval. Conversely, suppliers that view PPAP as a means of demonstrating their ability to produce a product will typically form long-term partnerships with their OEM customers.

A properly prepared, PPAP-compliant cable assembly will not only enable you to obtain OEM Approval but also provide a basis to continue producing a quality product, reduce risk, and maintain a sustainable relationship with the OEM.

FAQs

OEM buyers use PPAP to confirm that a cable supplier can consistently meet design, quality, and production-volume requirements under real-world manufacturing conditions.

Level 3 is most common because it includes the PSW, production samples, and complete supporting documentation.

Design records, PFMEA, control plans, MSA studies, dimensional data, electrical test results, and the PSW are typically the most critical.

They focus on crimp reliability, electrical continuity, measurement accuracy, traceability, and long-term process stability.

No. Many industrial, energy, agricultural, and automation OEMs require PPAP-style approvals for cable assemblies used in harsh or mission-critical environments.

.avif)

Sam Wu is the Marketing Manager at Romtronic, holding a degree in Mechatronics. With 12 years of experience in sales within the electronic wiring harness industry, he manages marketing efforts across Europe. An expert in cable assembly, wiring harnesses, and advanced connectivity solutions, Sam simplifies complex technologies, offering clear, actionable advice to help you confidently navigate your electrical projects.