Wiring harnesses are critical in industrial machinery, medical devices, and automotive systems. These organized bundles of insulated wires must transmit power and signals reliably. Yet even minor faults—like a cracked wire or loose connector—can cause significant problems (dead devices, erratic sensors, or unplanned shutdowns).

In practice, common harness failures fall into several key categories: environmental and mechanical stress, electrical short or open circuits, connector or termination issues, and manufacturing or assembly defects. The table below summarizes these fault types, their typical causes, and symptoms.

| Fault Category | Common Causes | Typical Symptoms |

|---|---|---|

| Short circuit | Insulation breakdown, moisture intrusion, and wire chafing | Fuses/blowers trip, unexpected shorts, overheating |

| Open circuit (broken wire) | Wire breakage (vibration fatigue, cutting), loose contacts | Devices lose power or signal; circuits are inactive |

| Connector/pin failure | Corrosion/oxidation, loose/misaligned pins, poor crimping | Intermittent connections, voltage drops, erratic behavior |

| Insulation damage | Heat aging, abrasion, chemical attack | Exposed conductors, risk of shorts or sparks |

| Overload/overheating | Undersized wire gauge, excessive current | Melted insulation, burnt wires, fire hazard |

Environmental and Mechanical Stress

Extreme temperatures, moisture, vibration, and abrasion are prime culprits. Harsh heat or cold can make insulation brittle or cause it to delaminate, while prolonged exposure to UV, chemicals, or oil can degrade the jacket. High humidity or contamination also invites corrosion and shorts. Over time, constant vibration causes wires to rub against each other or equipment frames, wearing through insulation.

In automotive and machinery applications, loose harnesses may chafe against sharp edges or moving parts, eventually cracking the jacket or snapping conductors. Even rodents in industrial or medical settings can chew through wiring, leading to sudden opens or shorts.

These mechanical stresses often manifest as insulation damage or wire breaks: a harness may exhibit exposed copper strands or broken conductors, risking either open circuits or unintended shorts (see table rows 2 and 4).

Electrical Shorts and Opens

Wiring harnesses fail most noticeably as shorts or open circuits. A short circuit occurs when two conductors touch (or one touches ground) unexpectedly, causing excess current flow. This often blows fuses or trips breakers. Short circuits are commonly caused by insulation failure (see above) or moisture, which creates unintended conductive paths. In the table above, shorts are tied to exposure and chafing.

By contrast, an open circuit means a break in continuity—no current flows. Opens occur when a wire fractures (due to fatigue or bending) or a connector pulls loose. Symptoms include powerless devices or “dead” signals. For example, a broken automotive sensor wire may shut down an engine subsystem.

In medical devices, even a single open may disable safety alarms or life-critical functions. As noted by harness experts, manufacturing defects (like a bad crimp or poor material) frequently lead to open circuits or intermittent connections. Routine continuity testing and inspection can catch these issues before deployment.

Connector and Termination Issues

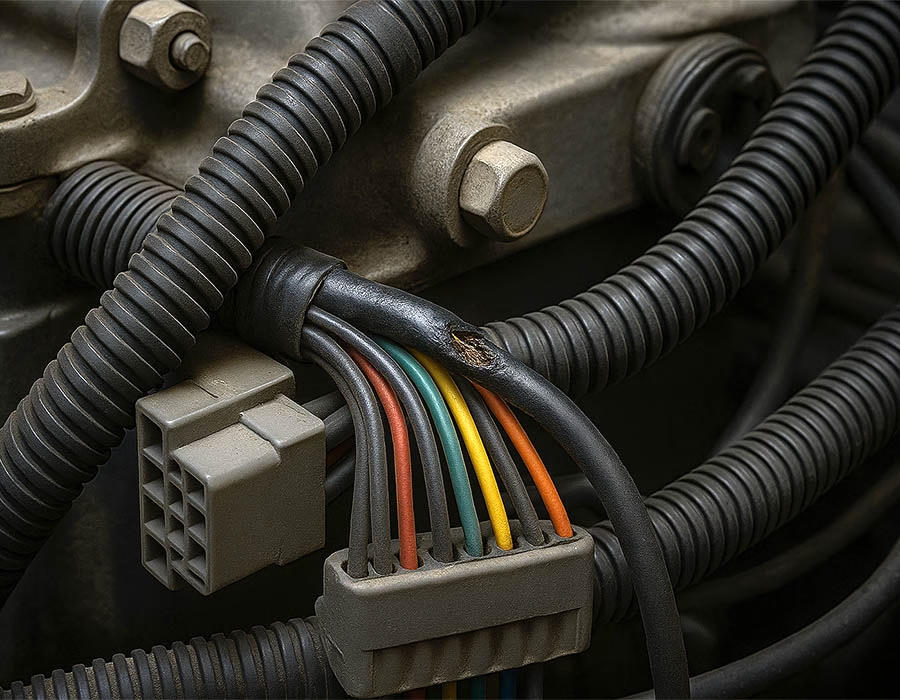

Connectors and terminations are another weak point. A pin that isn’t appropriately seated or a poorly crimped terminal can create high resistance or intermittent contact. Common faults include corroded contacts, bent or missing pins, and loose connectors that vibrate. For instance, in automotive wiring, the harness plug may suffer from terminal oxidation or deformation, causing poor contact that can disrupt engine signals. Similarly, improper crimping can slice strands or leave spare copper exposed.

In short, even if the wires themselves are sound, a faulty connector will break the circuit. Warning signs are flickering indicators, intermittent sensor readings, or systems that fail under vibration or movement. Ensuring high-quality terminals and secure, well-aligned connectors is crucial to avoid this class of faults.

Manufacturing and Assembly Defects

Beyond operational stresses, some hardware faults originate during the design or build process.

- Design mistakes, such as undersized wires, can cause overheating or voltage drop. If a harness is not built to handle the required amperage, it may heat its insulation under load. As iConn Systems notes, getting the wire gauge wrong or mis-measuring lengths “can quickly create problems, such as overheating, improper fit or alignment”.

- Assembly mistakes are also common, including mis-wiring (swapping circuits), loose crimps or solder joints, and tangled or kinked bundles, all of which invite failure. A harness technician who over-crimps can cut strands, just as one who under-crimps leaves weak terminations. Even complex harness layouts can trip up automated machines if the setup is off.

- Finally, poor materials can sabotage a harness: cheap copper alloys, substandard insulation, or inadequate over-molding let heat, vibration, and contaminants wreak havoc.

In practice, manufacturers find that nearly every faulty harness failure can be traced back to a design or build defect.

Mitigation and Design Tips

- Preventing harness faults begins in design and quality control.

- Using proper wire gauges and high-grade insulation guards against overheating and aging.

- Engineers should route harnesses away from heat sources and sharp components, adding strain relief where needed.

- Robust crimping tools and jigs, combined with automated pull tests, ensure that connectors are securely fastened before installation.

- Environmental seals (overmolds or boots) can keep moisture and debris out of connectors in harsh conditions.

- Routine inspection—looking for cracked insulation or green corrosion—and electrical testing (continuity, resistance) catch faults early.

In short, attention to detail in materials, assembly, and layout dramatically reduces hardware failures. The table above highlights how each fault has specific triggers and symptoms, guiding targeted checks.

Conclusion

Wiring harness failures are frustratingly common but well understood. In industrial machinery, medical equipment, and vehicles alike, the same basic culprits recur: wires cracked or abraded by heat and motion, shorts caused by moisture or chafing, connectors that lose contact, and any error in assembly or material. Addressing these requires systematic design, high-quality components, and careful installation.

Manufacturers with in-house capabilities, such as custom cable houses, can implement these best practices efficiently. For example, Romtronic’s in-house engineering and production ensure each harness is built and tested to specification, reducing the risk of these common faults. By following tight process controls and design reviews, engineers can minimize downtime and ensure that wiring harnesses remain reliable throughout their service life.

.avif)

Alex Wang is the Marketing Manager at Romtronic, with a degree in International Business and over seven years of experience in the electronic cable and wire harness industry. He leads marketing efforts across North and South America, combining deep industry knowledge with strong sales experience.

In addition to overseeing global marketing strategy, Alex is also responsible for content development and editorial coordination, ensuring that Romtronic’s messaging remains clear, consistent, and engaging. His strength in market analysis and customer-focused approach helps clients make more informed purchasing and sales decisions.