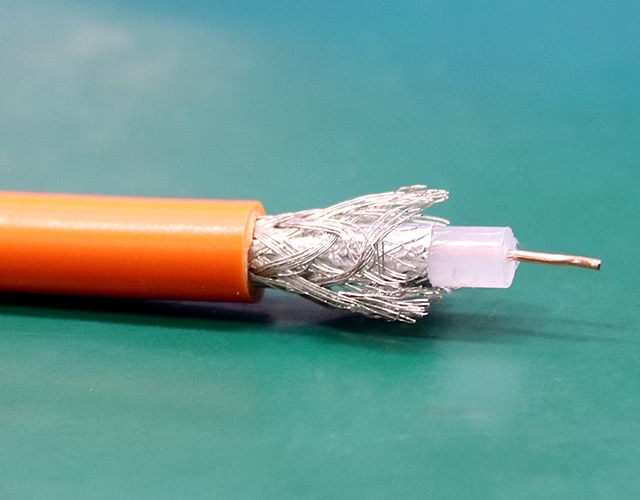

Reliable, high-performance BNC cables designed for broadcast, RF, surveillance, and measurement applications.

Romtronic manufactures custom BNC cable assemblies to meet your exact requirements. With in-house production, testing, and overmolding, we deliver solutions that are accurate, durable, and fast to market.

Our customised BNC cable assemblies

Our BNC cable manufacturing process

Advantages of our customized BNC cables

- Experienced, 28 years professional cable assembly and wiring harness manufacturer.

- Customization capability, providing customized solutions according to customers’ needs.

- Quality assurance, using advanced manufacturing processes and quality testing equipment.

- Technological innovation, continuously improving product performance and quality.

- Comprehensive customer service, including consulting, customized design, manufacturing and after-sales support.

Frequently Asked Questions (FAQs)

Q1: What types of BNC cables do you customize?

We offer custom BNC cables with 50-ohm or 75-ohm impedance, suitable for RF, video, broadcast, CCTV, and instrumentation applications. Available in straight or right-angle connectors, with various coaxial cable types (RG58, RG59, RG174, etc.).

Q2: Can you produce BNC cables for both analog and digital signals?

Yes. Our BNC cable assemblies support analog signals (such as CVBS video) and digital formats like SDI (Serial Digital Interface), HD-SDI, and 3G-SDI, depending on your bandwidth and shielding needs.

Q3: Do you offer custom lengths, colors, and overmolding for BNC cables?

Absolutely. We can manufacture cables in custom lengths, jacket colors, and offer strain reliefs or overmolded connectors for durability and branding.

Q4: Are your BNC cables tested before shipment?

Yes. Every BNC cable is 100% tested for continuity, impedance, and signal integrity. High-frequency versions are also tested for return loss and insertion loss.

Q5: Can you provide bulk production as well as low-volume or prototype orders?

Of course. We support everything from small-batch prototypes to large-volume production, with fast turnaround and consistent quality control.

Get in Touch for Custom BNC Cable Solutions

Romtronic offers custom BNC cable assemblies for a variety of applications, including broadcast, test and measurement, surveillance systems, and RF communications. We provide flexible options for impedance (50Ω or 75Ω), connector styles, shielding, and cable lengths to suit your technical needs.

To request a quote, sample, or technical consultation, feel free to contact us through the form on this page or using the contact details below — our team will respond within 12 hours with tailored support.

📧 Email: info@romtronic.com

📞 Phone: (+86) 199-2816-5824

Romtronic delivers reliable, high-performance BNC cable solutions trusted by global OEMs and system integrators.