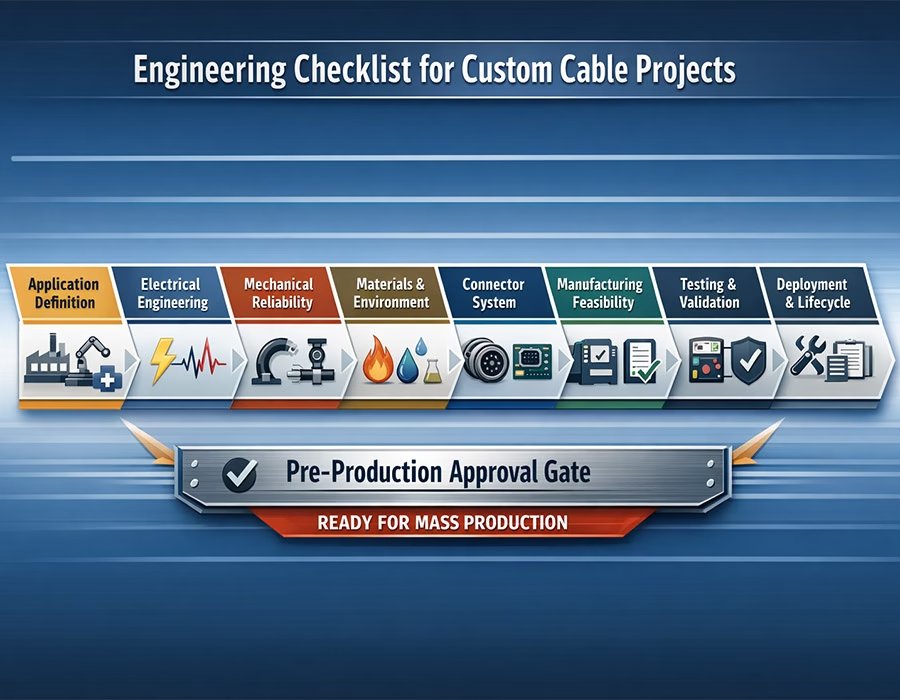

Cable assemblies are not “off-the-shelf” products; they are custom-crafted interconnect systems that directly affect your electrical performance, mechanical reliability, regulatory compliance (UL certification), and long-term safety in the field. The majority of cable assembly failures occur in the early stages of development (rather than during production), primarily due to unclear requirements for electrical/mechanical/environmental conditions, or insufficient consideration of manufacturability.

This engineering guide provides a structured project management checklist covering the entire lifecycle of your cable assembly, which should reduce redesign cycles, eliminate unknown risks, and provide a solid basis for delivering high-quality cable assembly products.

1. Define Application and Project Boundaries

Before designing a cable, clearly define its operating context.

Checklist:

- End-use application: industrial, automotive, medical, data, consumer

- Installation method: internal, external, drag chain, robotic, panel mount

- Routing path and space limitations

- Temperature and storage range

- Exposure to water, dust, UV, oils, fuels, chemicals

- Vibration and mechanical shock

- EMI/EMC sensitivity

- Regulatory compliance: UL, RoHS, REACH, ISO, IATF, medical standards

2. Electrical Engineering Requirements

The electrical definition forms the functional core of the assembly.

Checklist:

- Operating and peak voltage per conductor

- Current and conductor size (AWG/mm²)

- Signal type: power, data, RF, hybrid

- Data rate, bandwidth, or frequency range

- Shielding strategy (overall, individual, foil, braid)

- Grounding requirements

- Crosstalk, attenuation, and EMI targets

- Controlled impedance where applicable

3. Mechanical and Physical Reliability

Mechanical failure is a leading cause of field issues.

Checklist:

- Cable construction: solid vs stranded, twisted pairs, coaxial, multi-core

- Diameter limits and bend radius

- Flex life (static vs dynamic applications)

- Tensile strength and pull resistance

- Strain relief design: boots, overmolding, clamps

- Abrasion and wear resistance

- Vibration and shock tolerance

4. Materials and Environmental Considerations

Material choice determines survival in the field.

Checklist:

- Conductor material: bare copper, tinned, silver-plated

- Insulation: PVC, PE, XLPE, PTFE, silicone, TPE

- Jacket performance: abrasion, oil, chemical resistance

- UV, flame, and IP-rated protection

- Environmental threats: temperature extremes, moisture, chemicals

- Regulatory compliance: RoHS, REACH, UL, CSA

5. Connector and Interconnect System Design

Connector failures are common—treat them as part of the system.

Checklist:

- Connector type, manufacturer, part number

- Pin count, gender, keying, polarization

- Mating cycle rating, locking mechanism

- Contact plating, waterproofing, and heavy-duty options

- Termination method: crimp, solder, IDC

- Pinout map and wiring diagram

- Connector-side strain relief

6. Manufacturing Feasibility and DFM Review

Ensure design can be consistently manufactured.

Checklist:

- Process complexity: cutting, stripping, soldering, crimping, overmolding

- Automation feasibility

- Critical process control points

- Yield, traceability, and labeling risks

- Pilot run and production scalability

- Cost sensitivity to materials or labor

7. Testing, Validation, and Quality Control

Testing validates both design and manufacturing stability.

Checklist:

- Continuity and wiring verification

- Insulation resistance and hipot testing

- Impedance and TDR testing for high-speed/RF cables

- Mechanical tests: pull, flex, insertion cycles

- Environmental and aging tests

- Visual inspection

- Prototype and pilot approval before mass production

8. Installation, Deployment, and Lifecycle Considerations

Field reliability depends on proper handling and deployment.

Checklist:

- Pulling tension limits and handling

- Routing protection: conduits, trays, lacing

- Shield grounding execution

- Connector mating and torque standards

- Identification and labeling

- Serviceability and replacement accessibility

- On-site acceptance tests

9. Documentation, Compliance, and Lifecycle Management

Documentation transforms custom cables into controlled engineering products.

Checklist:

- Cable drawings, wiring schematics, and BOM

- Process and inspection plans

- Test reports and validation records

- Compliance documentation

- Change control and revision history

- Supply chain continuity assessment

10. Pre-Production Final Checklist

Before approving mass production, confirm:

- ☑ Application boundaries defined

- ☑ Electrical parameters frozen

- ☑ Mechanical risks reviewed

- ☑ Environmental threats addressed

- ☑ Connector system verified

- ☑ Materials validated

- ☑ Manufacturing feasibility approved

- ☑ Testing completed

- ☑ Documentation released

- ☑ Supply chain risks assessed

This final gate prevents surprises and ensures smooth production.

Conclusion

Engineering custom cable assemblies as complete system assemblies is crucial to their success. The goal of this checklist is to organize and verify that design, materials, mechanical/electrical decisions, etc., are consistent. By doing so, you reduce risk while increasing certainty for long-term trust in the product. Here at Romtronic, we begin every custom cable assembly project with an engineering review—not just a price quote. We know that trust in a custom cable assembly is created well before we build it, during the engineering phase.

.avif)

Sam Wu is the Marketing Manager at Romtronic, holding a degree in Mechatronics. With 12 years of experience in sales within the electronic wiring harness industry, he manages marketing efforts across Europe. An expert in cable assembly, wiring harnesses, and advanced connectivity solutions, Sam simplifies complex technologies, offering clear, actionable advice to help you confidently navigate your electrical projects.