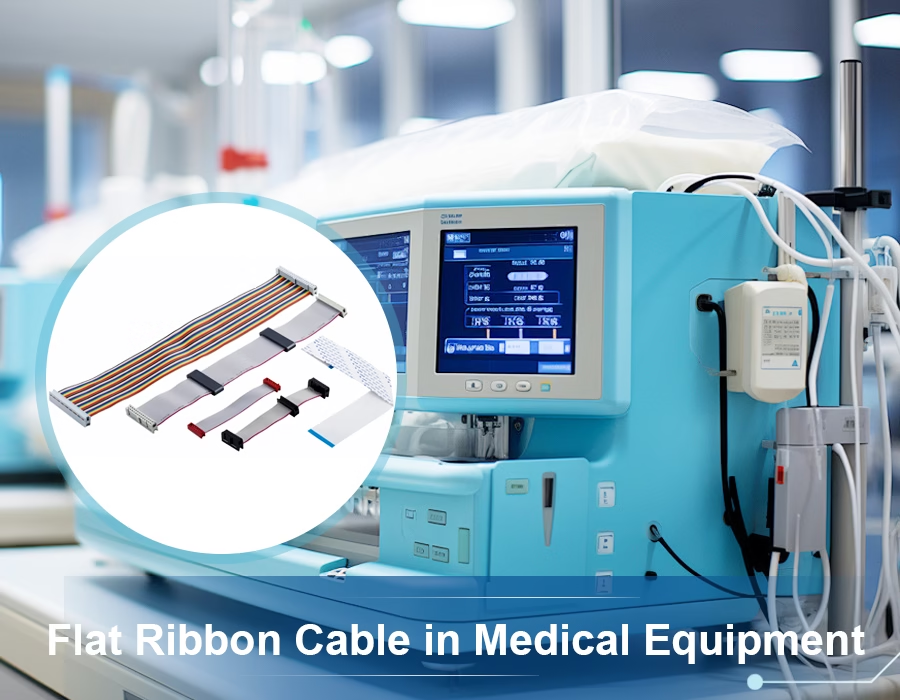

Modern medical devices often pack complex electronics into tight spaces. Flat ribbon cables – wide, thin connectors made of many parallel wires – help solve these design challenges. They carry multiple signals or power lines in a compact form, making them ideal for devices such as patient monitors, imaging systems, and laboratory instruments. Ribbon-style cables appear everywhere, from ECG/EEG machines to portable ultrasound units, precisely because their flat shape and organized conductor layout make assemblies neat and reliable.

Why Flat Cables Are Ideal for Medical Devices

Medical equipment demands cables that are small, flexible, and safe. Flat ribbon cables meet these needs in several ways:

- Space-saving design: A flat cable’s low-profile, multi-conductor layout fits into slim enclosures. This makes it perfect for compact devices with crowded circuit boards. For example, many patient monitors use ribbon cables to neatly consolidate dozens of signals in a limited space.

- High flexibility and durability: These cables bend, fold, and twist much more easily than stiff wire bundles. Specialized “high-flex” flat cables can endure millions of bends (often over 150 million!) without breaking. That’s crucial in equipment with moving parts or frequent repositioning (like surgical carts or analyzers on robotic tracks).

- Hygienic, sterilizable materials: Medical flat cables can utilize biocompatible jackets (such as PVC, silicone, or fluoropolymers) that resist chemicals and withstand sterilization. Many designs are rated for USP Class VI (skin-safe) and can be wiped clean or even autoclaved without degrading. This lets technicians disinfect the cables between patients.

- Multi-signal organization: A single flat cable can carry power lines, data channels, and even optical or fluid conduits simultaneously. This reduces clutter and connector count. For instance, a single 40-conductor ribbon cable can replace dozens of individual wires, simplifying assembly and reducing the number of failure points.

These benefits translate to safer, more reliable equipment. The table below summarizes key flat-cable features and why they matter in medical gear:

| Feature | Medical Benefit |

|---|---|

| Slim, multi-wire layout | Saves space in tight devices and boards |

| Extreme flex life | Withstands constant motion (drag chains, robotic arms) |

| Chemical-resistant jacket | Can be wiped/disinfected and sterilized |

| Fixed conductor spacing | Stable impedance and low crosstalk for clean signal transmission |

| Standard IDC connectors | Fast mass-termination of all wires at once, simplifying assembly |

Typical Medical Applications

Flat ribbon cables are everywhere in modern healthcare devices. Here are some common examples:

- Patient Monitoring Systems (ECG/EEG/MEG machines): Within these bedside monitors, ribbon cables connect sensor inputs to display panels. Their low profile and multiple conductors efficiently handle the many bio-signal channels.

- Diagnostic Imaging (X-ray, CT, MRI, Ultrasound): Imaging detectors and moving gantries use flat cables to route high-speed data. The consistent impedance and shielding options help maintain image quality. Cables in ultrasound probes also benefit from being bendable for easier handling.

- Lab Analyzers and Automation: Automated blood analyzers and chemistry analyzers often have robotic sample handlers. Flat cables (sometimes in drag chains) connect motors and sensors, surviving millions of cycles—their flexibility and cleanability make them suitable for sterile lab environments.

- Surgical and Endoscopy Equipment: Minimally invasive surgical tools and endoscopes use miniature flat cables for video, lights, and controls. These cables must be sterilizable and robust despite their tiny size. Ribbon cables can also integrate power, data, and even fiber optics into a single assembly.

- Portable Medical Electronics: Devices such as handheld monitors or infusion pumps often utilize flat cables for their lightweight, compact wiring. Their uniform shape avoids kinks and simplifies installation in handheld or wearable designs.

| Medical Device | Role of Ribbon Cable | Advantage in Use |

|---|---|---|

| Patient Monitor (ECG/EEG) | Connects sensors, board, and display internally | Consolidates many channels in slim chassis |

| Imaging Systems (MRI/CT) | Routes signals to detectors and control units | Maintains signal integrity in tight spaces |

| Ultrasound Machine | Wired connections in probe and console | Flexible for repeated probe movements |

| Lab Analyzer (Bloodwork) | Links automated modules, motors, and sensors | Endures constant motion; easy to clean |

| Surgical Endoscope | Carries video/data wires through the insertion tube | Small diameter, biocompatible, sterilizable |

🔧 Need reliable flat ribbon cables for medical devices?

Romtronic delivers customizable flat ribbon cables designed for precision, flexibility, and long-term performance in healthcare applications.

👉 Talk to our experts today →

Technical and Installation Considerations

When designing or servicing medical equipment, engineers note several key points about flat ribbon cables:

- Connector Type: Most flat cables use insulation displacement connectors (IDC). These connectors clamp down on the parallel wires simultaneously, allowing for fast assembly. Standard IDC sockets match the cable’s pitch (often 1.0 mm or 1.27 mm). This means replacement or custom ribbon harnesses are easy to swap during maintenance.

- Materials and Standards: Medical ribbons often use UL‑listed materials and meet IEC 60601 safety standards. Biocompatible jackets (like silicone or specialized PVC) comply with sterilization protocols. Cables are also tested for biocompatibility to prevent any toxic or allergic reactions.

- Durability Testing: Manufacturers verify that flat cables can withstand the expected number of bending cycles. For example, some products are rated for over 150 million flex cycles at tight bend radii. They may also feature oil/chemical resistance coatings, so routine cleaning (ethanol, isopropyl wipes) doesn’t degrade the insulation.

- Shielding and Noise: Sensitive electronics may require flat cables with foil or braid shielding. Shielded ribbon cables prevent electromagnetic interference (EMI) from distorting critical signals. Many medical flat cables come in shielded versions for EMI/EMC compliance.

In practice, flat ribbon cables must be chosen to match the device’s specific requirements: the number of conductors, the required bend radius, and the environmental needs. Engineers often consult manufacturers’ catalogs (which list lengths, pin counts, and materials) to pick the correct part. Popular options range from a few conductors to 64 or more, and cable widths can be tailored to fit circuit board headers precisely.

FAQs

Flat ribbon cables consist of multiple parallel insulated wires in a single, flat strip. This compact, space-saving design makes them ideal for use in tight spaces within medical machines.

Medical-grade flat cables are built to strict safety standards. They often have UL/CSA safety certifications and use durable, biocompatible insulation.

Avoid twisting or bending the cable sharply. For example, guidelines recommend using gentle curves (at least about six times the cable’s thickness) and securing the cable every few feet with clips or ties to prevent sagging. Also, ensure the cable matches your device’s connector and pin count – flat wires come in many sizes and must match the port.

Most flat medical cables have smooth, sealed jackets, allowing them to be wiped clean. You can gently disinfect them with approved wipes or cleaners, taking care not to soak the connectors. Inspect cables regularly for any cuts or wear. Since they’re made to endure sterilization, routine cleaning according to the manufacturer’s instructions is generally safe.

They can last a very long time. Many are rated for tens of millions of bend cycles – for instance, some medical flat cables survive over 150 million flexes. With regular use and proper handling (avoiding sharp bends), a high-quality flat cable will typically serve for years before needing replacement.

No, they’re generally quite affordable. The flat design is simpler to manufacture, making these cables cost-effective. Standard flat cables (a few inches or feet long) often cost on the order of a few dollars each. Prices rise if you require special shielding or medical-grade materials, but flat cables are generally less expensive than equivalent round bundles.

Not usually. Flat ribbon cables come in many widths (number of wires) and with different connectors. You must use a cable that matches your device’s specifications. In practice, replacements are typically ordered by the equipment model or from the original manufacturer to ensure an exact fit.

📌 Need reliable cable assemblies for your next medical innovation?

Romtronic partners with leading healthcare manufacturers to deliver flat ribbon cables that ensure precision, safety, and long-term performance. From prototyping to mass production, our engineers are ready to help bring your device to market faster.

👉 Request a free project assessment →

Conclusion

In short, flat ribbon cables quietly power a vast range of medical equipment by packing complex wiring into neat, reliable assemblies. Their space-saving form, flexibility, and ability to be cleaned or sterilized make them ideal for a wide range of applications, from patient monitors to surgical robots. The next time you see a sleek new medical device, remember that some of its performance owes itself to these humble flat cables running behind the scenes. Their blend of technical finesse and practical convenience ensures that modern healthcare instruments run smoothly.

.avif)

Sam Wu is the Marketing Manager at Romtronic, holding a degree in Mechatronics. With 12 years of experience in sales within the electronic wiring harness industry, he manages marketing efforts across Europe. An expert in cable assembly, wiring harnesses, and advanced connectivity solutions, Sam simplifies complex technologies, offering clear, actionable advice to help you confidently navigate your electrical projects.