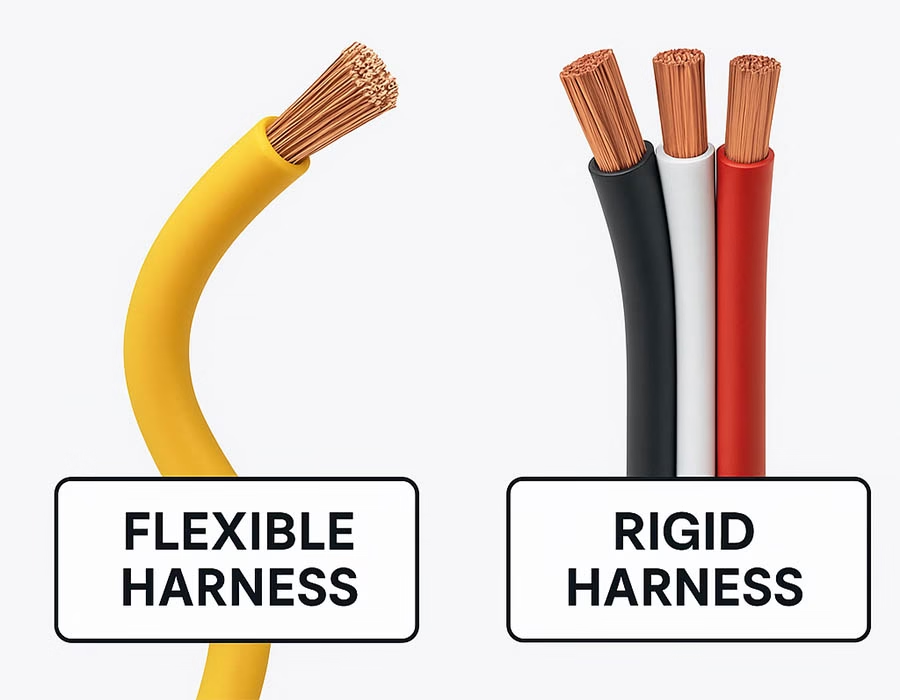

A wire harness (or cable assembly) bundles multiple wires into a single unit for neat routing and reliable connections. Designers and buyers in automotive, aerospace, robotics, medical, and consumer electronics must decide between a flexible harness (built for movement and tight bends) and a rigid harness (built for fixed installations and heavy-duty use).

Flexible harnesses typically utilize fine-stranded conductors and soft insulation to bend around tight radii, whereas rigid harnesses employ thicker cables and more robust jackets for stationary wiring. Understanding their differences in construction, materials, and certifications helps choose the right solution.

What is a Wire Harness?

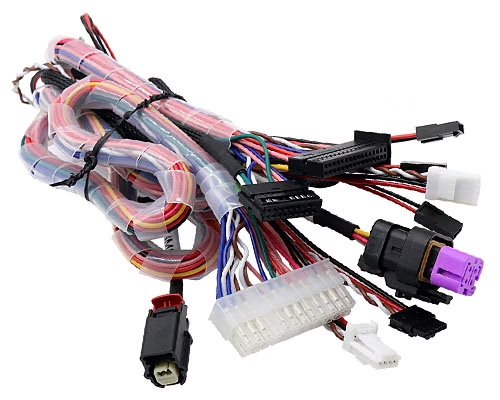

A wire harness is a bundle of cables and wires wrapped in insulation and protective sleeving. Instead of running loose wires, a harness groups them – often with ties or loom tubing – to simplify assembly and improve safety. This all-in-one “drop-in” approach ensures each conductor is correct and provides organized routing. Harnesses range from simple jumper assemblies to complex multi-branch cables for power, signal, and data. The primary difference between flexible and rigid harnesses lies in their ability to handle movement and bending.

Flexible harnesses use fine, multi-stranded copper wire and soft jacketing to allow tight bends and motion. They often incorporate elastic materials, such as silicone or Teflon (PTFE), for insulation. These materials offer excellent flexibility and heat resistance, making the harness suitable for use with moving parts or in extreme temperature applications. In contrast, rigid harnesses use heavier-gauge (often coarse-stranded or solid) wires with standard PVC or nylon jackets. They are meant for fixed installations (like control panels or chassis wiring) where the cable stays put. Rigid harnesses are sturdy and more straightforward, but cannot twist or flex repeatedly without fatigue.

Flexible vs Rigid: Key Differences

- Flexibility & Bend Radius: Flexible harnesses can bend around tight corners and flex continuously. They are rated for repeated motion (e.g., robotics or moving machine parts) and use high-strand-count wire for ductility. Rigid harnesses have a larger minimum bend radius and are only intended for occasional movement during installation. Bending a rigid harness beyond its limit can break strands or damage insulation.

- Weight: Flexible harnesses are generally lighter. Fine-stranded wires with thin, pliable jackets (like silicone or PTFE) reduce mass, critical in aerospace or portable electronics. Rigid harnesses utilize thicker conductors and jackets, making them heavier but easier to assemble.

- Durability & Motion: Flexible harnesses excel in environments with vibration and motion. For example, in robotic arms and industrial machines, harnesses must endure millions of flex cycles while resisting abrasion and torsion. Rigid harnesses are durable in static environments – they often tolerate higher mechanical strain or pull in fixed routes – but repeated bending can cause them to fail.

- Installation: Flexible harnesses can easily snake through confined paths and around components. Rigid harnesses are often preformed or routed through channels and may require connectors or brackets, as they maintain their shape.

- Cost: Flexible harnesses are more expensive per foot because they require specialized wire (silicone/PTFE jackets, fine strands) and labor to bundle and shield them. Rigid harnesses, on the other hand, utilize off-the-shelf cable and a more straightforward assembly, making them generally less expensive.

- Typical Use Cases: Flexible harnesses are preferred for moving assemblies, such as automotive doors (where cables flex with the hinge), robotics, aerospace actuators, or wearable/medical devices. Rigid harnesses are used in fixed installations, such as wiring behind dashboards, inside appliances, or industrial panels.

Below is a concise feature comparison:

| Feature | Flexible Harness | Rigid Harness |

|---|---|---|

| Construction | Fine-stranded copper conductors; soft jacketing (silicone, PTFE) | Thicker/coarse conductors; standard insulation (PVC, nylon) |

| Flexibility | High – designed for tight bend radii and motion | Low – rigid or inflexible; not for repeated bending |

| Bend Radius | Very small (e.g. a few cable diameters) | Larger, limited by insulation stiffness |

| Vibration/Motion | Excellent (e.g. millions of flex cycles) | Limited (best used stationary) |

| Weight | Lower (lighter wires and jackets) | Higher (heavier gauge and insulation) |

| Materials | Specialty jacketing (silicone, PTFE, FEP); high-strand wire | Common jackets (PVC, rubber, PU); standard copper wire |

| Applications | Moving parts (robots, cranes, aerospace actuators) | Fixed wiring (panels, frames, appliances) |

| Cost | Higher (special materials, more labor) | Lower (standard components) |

| Typical Certifications | UL-recognized flex cable; RoHS/REACH; meet IPC standards | UL-listed/recognized; meet IPC standards |

Materials and Specifications

Wire harnesses use copper conductors (often tin-plated for solderability) with various insulation materials. Common jacket materials include PVC (polyvinyl chloride) for general purpose, XLPE (cross-linked polyethylene) for flame/oil resistance, PUR (polyurethane) for wear and oil resistance, and silicone or Teflon (PTFE, FEP) for high-temperature flexibility. For instance, PTFE jackets are prized for dielectric strength and flexibility in high-frequency or military cables. At the same time, silicone provides a broad temperature range and biocompatibility (suitable for medical or harsh environments). Some harnesses also utilize braided sleeving (made from nylon, polyester, or fiberglass) or corrugated tubes for added abrasion protection.

Engineers select wire AWG size based on current load; flexible harnesses often use wonderful strands to improve bendability, whereas rigid harnesses may use coarser wire. Cable categories (e.g., UL 1007, UL 1061) define voltage and insulation thickness requirements. Many modern harnesses also utilize lightweight aluminum wire in specialized cases (e.g., some chassis wiring) to reduce weight. Spec sheets will detail ampacity, voltage rating, and insulation class. High-performance harnesses may utilize mineral-insulated (MI) cables or shielded pairs for applications in extreme conditions. Ultimately, material choice is driven by environment: e.g., outdoor automotive harnesses use oil- and UV-resistant jackets (UL styles), while aerospace harnesses may require flame-retardant, low-smoke materials.

Industry Applications

Wire harnesses are ubiquitous across industries. Typical applications include automotive wiring (engine harness, chassis, and body looms), aerospace/military (avionics, drones, weapons systems), and consumer appliances (TVs, refrigerators). They also power medical devices, telecommunications infrastructure, and industrial equipment. For example, in robotics and automation, harnesses must handle continuous flex and even extreme motion – moving joints on a robot or an elevator cable carrier may cycle millions of times. In transportation, harnesses are used in traffic control systems and electric vehicle battery packs. Medical device harnesses need biocompatible insulation and repeatable reliability. Consumer and lighting industries use harnesses to simplify complex electronics assembly (smart appliances, LED arrays, etc.).

Key industries include Automotive (cars, EVs, trucks), Aerospace and defense (aircraft, drones), Robotics and industrial Machinery (factory automation, AGVs), Medical (imaging, monitors, implants), and Electronics (computers, appliances). Each sector has specific requirements (e.g., the automotive industry often requires IATF-certified harnesses; the military sector requires MIL-SPEC compliance).

Certifications and Standards

Quality and safety standards are critical for wire harnesses. Key certifications include:

- UL/CSA – Many harness components (wires, connectors) are UL-listed or UL-recognized. The UL mark indicates that the product has been tested and meets UL safety standards. UL/CSA labeling is common for appliances and vehicles in North America.

- IPC/WHMA-A-620 – The industry standard for cable and harness assemblies. IPC/WHMA-A-620 defines the acceptability of solder joints, crimps, insulation, etc. – essentially the rulebook for proper harness assembly. Manufacturers will classify harnesses into quality classes (1–3) based on application (Class 3 being for the highest performance/military).

- ISO 9001 & IATF 16949 – Quality management certifications. Most reputable harness makers (especially in the automotive industry) are ISO 9001 certified and IATF 16949 (for the automotive supply chain). ISO 13485 may apply to medical device harnesses. RoHS/REACH compliance is expected for most industries.

- MIL-SPEC & Others – For aerospace/military, MIL-STD or NADCAP requirements apply. Some harnesses must meet FDA/QSR for medical manufacturing. Wire traceability (UL/CSA listings, heat resistance, flame rating) is verified in all cases.

Working with suppliers that hold these certifications ensures the harness will meet regulatory and reliability requirements. For example, Romtronic’s factory is certified to ISO 9001, ISO 13485, and IATF 16949, showing adherence to international quality standards.

Choosing the Right Harness and Partner

In summary, choose flexible harnesses when cables must move, bend sharply, or fit in a confined space, and rigid harnesses for simple, stationary wiring runs. Consider environmental factors (such as vibration, temperature, and chemicals), electrical needs (including voltage and EMI/RFI), and regulatory requirements. Verify that the harness design (wire gauge, strands, insulation) satisfies current and thermal specs and that bend radii are respected during installation.

As projects become complex, partnering with an experienced manufacturer is key. For example, Romtronic is a seasoned custom harness supplier with over 28 years of experience in OEM/ODM services. Romtronic holds ISO 9001 and IATF 16949 certifications, serving global markets across automotive, medical, robotics, and industrial machinery sectors. Their engineering team can help select flexible or rigid designs, materials, and harness geometry to meet your specifications. By working with a trusted manufacturer like Romtronic, engineers and procurement teams can ensure high-quality, UL/IPC-compliant harness assemblies that meet the intended application requirements.

.avif)

Sam Wu is the Marketing Manager at Romtronic, holding a degree in Mechatronics. With 12 years of experience in sales within the electronic wiring harness industry, he manages marketing efforts across Europe. An expert in cable assembly, wiring harnesses, and advanced connectivity solutions, Sam simplifies complex technologies, offering clear, actionable advice to help you confidently navigate your electrical projects.