Cable assemblies in contemporary electronic and technical production are seldom bought off the shelf; they are created as part of a more intricate assembly of components and are subjected to extremely strict standards of power, control signal, and signal transmission under conditions that are extremely harsh, as you can see.

HMLV (high-mix, low-volume) production is the best option for this type of production because, unlike traditional mass manufacturing, it focuses on flexibility, accuracy, and customization of cable assemblies rather than on producing them quickly and in bulk.

Many industries are using HMLV to produce specialized, tailored cable assemblies with a low risk of failure, including EVs (electric vehicles), medical devices, robotics, and the aerospace (aviation) industry. In the same way, a custom tailor designs a suit specifically for a person, HMLV customizes the assembler to meet each client’s requirements.

1. Defining High-Mix Low-Volume in Cable Assembly

HMLV is defined by:

- High Mix: Dozens or even hundreds of unique cable designs with different connectors, wire types, shielding, overmolding, and lengths.

- Low Volume: Small batch sizes, often from a few units to a few hundred, with frequent production changes.

This approach enables manufacturers to meet customization requirements, respond quickly to design changes, and maintain consistent quality across diverse assemblies.

Key Characteristics of HMLV Cable Assembly:

| Characteristic | Description |

|---|---|

| High Variety, Low Quantity | Many different cable designs, each produced in small batches. |

| Customization | Cables are built to unique customer specifications. |

| Frequent Changeovers | Production lines switch quickly between different materials and processes. |

| Complexity Management | Managing multiple parallel part numbers with short lead times is essential. |

2. Key Challenges in HMLV Production

Producing many different cables in small quantities comes with engineering and operational challenges:

- Frequent Changeovers: Each new design requires tool adjustments, connector swaps, and recalibration of processes.

- Supply Chain Complexity: Hundreds of unique wires, terminals, and components must be tracked in real time using ERP/MES systems.

- Highly Skilled Labor: Technicians may handle a medical harness in the morning and a rugged industrial cable in the afternoon.

- Quality Consistency: Small batches magnify any variation. Each assembly must meet electrical, mechanical, and environmental standards.

- Engineering-Driven Process Control: Prototypes and pilot runs must transition smoothly to repeatable production.

3. Production Approach for HMLV Cable Assembly

Successful HMLV manufacturing relies on hybrid and flexible systems:

- Hybrid Automation: Automated cutting, crimping, and labeling integrated with manual steps.

- Modular Systems: Configurable machines allow quick adaptation to new designs.

- Digital Tools: ERP, MES, and AI manage complexity, track components, and optimize workflows.

Focus & Goals:

| Goal | Description |

|---|---|

| Adaptability | Flexible systems prioritize responsiveness over volume efficiency. |

| Precision & Quality | Engineering planning ensures reliable outputs across all assemblies. |

| Customer-Centric | Processes solve specific customer challenges, not just produce standard products. |

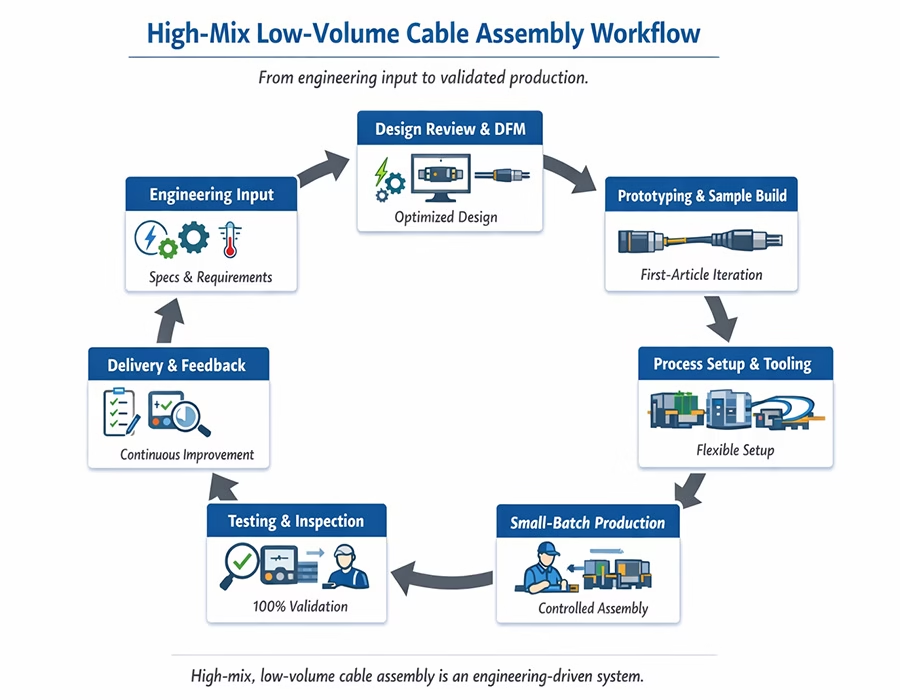

4. Typical HMLV Manufacturing Workflow

Even with variety, HMLV shops follow a disciplined workflow:

- Design & DFM Review: Engineers check drawings for manufacturability.

- Kitting: All components for each job are gathered into a job-specific kit.

- Preparation: Automated machines cut, strip, and print ID codes on wires.

- Assembly: Technicians lay wires on form boards to create harnesses.

- Termination: Connectors applied via crimping or soldering.

- Testing: 100% electrical testing (continuity, shorts, hipot) ensures no errors in small batches.

Pro tip: Even small batches must follow the same rigorous workflow as large-scale production. Consistency is everything.

5. Industry Applications

HMLV production is essential for industries that require high reliability and customization:

| Industry | Example Applications |

|---|---|

| Electric Vehicles (EVs) | High-voltage harnesses (1500V/120A), signal harnesses (CAN/LIN bus), fast-charging cables |

| Industrial Automation | Robotic cables (million-cycle bend life), sensor harnesses with EMC protection, high-frequency servo lines |

| Medical Devices | Endoscope cables (<3mm OD), patient monitor cables, surgical robot cables (sterilizable, biocompatible) |

These examples show the complexity and critical performance requirements of HMLV manufacturing.

6. Key Technical Metrics

| Metric Type | Parameters | Testing Standard |

|---|---|---|

| Electrical | Rated voltage 300–1500V; insulation resistance ≥100MΩ; dielectric test AC 1500V/1min | IEC 60227 / UL 758 |

| Mechanical | Bend life ≥1 million cycles; tensile strength ≥15N; vibration 50Hz–2000Hz | IEC 60068-2-6 / UL 2556 |

| Environmental | Operating temperature -40°C–125°C; salt spray ≥48h; flame rating VW-1 | IEC 60068-2-11 / UL 94 |

7. Production Management Strategies

To handle complexity, HMLV manufacturers implement:

- Advanced Planning & Scheduling (APS): Optimizes production sequences across multiple lines.

- Statistical Process Control (SPC): Monitors key process parameters in real-time.

- Value Stream Optimization: Reduces waste, improves throughput, and lowers unit cost.

- Supply Chain Coordination: Strategic suppliers and VMI systems ensure materials are available on time.

8. Why Companies Choose HMLV

HMLV is ideal for:

- Prototyping: Test new designs before mass production.

- Niche Markets: Low-volume, high-reliability products like MRI machines, satellites.

- Just-in-Time Manufacturing: Minimize inventory while responding quickly to changes.

Bottom line: HMLV is the “custom tailor” approach to cable assembly—flexible, precise, and engineered for your unique requirements.

9. Future Trends

- Smart Manufacturing: AI-driven quality prediction, digital twins, adaptive control.

- Advanced Materials: Lightweight alloys, halogen-free insulation, self-healing conductors, temperature-sensitive materials.

- Integrated & Modular Design: Cables with embedded sensors, smart data/power integration, plug-and-play standardized modules.

These trends make HMLV a core capability for the next generation of industrial, medical, and EV applications.

Conclusion: HMLV Is an Engineering Decision

The High-Mix Low-Volume cable assembly manufacturing process also includes many functions within an Engineering discipline. Success will depend upon process control, skilled labor, and adaptable systems.

Selecting a proper HMLV partner will help manage engineering risk, but price alone should not be the primary factor in your decision.

When cable assemblies are system-critical, supplier selection becomes an engineering decision, not a transactional one.

.avif)

Sam Wu is the Marketing Manager at Romtronic, holding a degree in Mechatronics. With 12 years of experience in sales within the electronic wiring harness industry, he manages marketing efforts across Europe. An expert in cable assembly, wiring harnesses, and advanced connectivity solutions, Sam simplifies complex technologies, offering clear, actionable advice to help you confidently navigate your electrical projects.